Form Traveller System Bridge Construction: Out-spanning Traditional Methods

The use of form traveller systems offers significant cost savings for bridge construction projects throughout the world. We've partnered with Miguel Barreto from ConstruGomes of Portugal to highlight the key aspects of form traveller systems: how they offer cost advantages over traditional construction systems, in what situations they can best be utilized, and how they function.

Form Traveller Bridge Construction

Form traveller specifics.

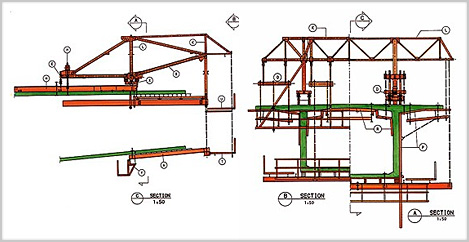

Form travellers can be employed during cantilevered concrete girder construction when a bridge pier can be used as a starting point. Opposite directions of span construction are facilitated by using the top of a pier as the initial anchor point for two separate form travellers (each pair of form travellers operates as a unit). Cantilevered construction is allowed by moving each pair of form travellers farther away from a pier in tandem. The weight is therefore always balanced, and the static forces on the pier maintain equilibrium. The incremental movement of each pair of form travellers is the critical path to project completion.

Work progress is limited to span increments of approximately 5 m (approx. 16') or 400 tons per week on each side of a pier. However, the key advantage of form travellers is their ability to span great distances in remote locations. If the contractor can access the piers, the bridge can generally be built with form travellers, including angled bridge decks with varying turn radii. Form travellers are preferred for building spans over deep valleys, waterways, and roads where access from the ground is a challenge and the number of piers is limited (especially for the central span).

- Form Traveller Delivery: Form traveller equipment can be trucked to the job site in multiple shipments or barged to the site if a bridge is being constructed over a navigable waterway.

- Form Traveller Operation and Training: Form travellers are powered by a hydraulic system, requiring the crews that operate them to receive specific training. The structural framework of the form traveller moves forward on rails anchored to the previously constructed span segments. The individual steel structural members of each form traveller are connected with pins to facilitate mobilization/demobilization.

- Form Traveller Installation: Form traveller equipment is assembled on the ground, and segments are then lifted by crane to their starting points on a specific bridge pier. Demobilization follows the same process in reverse. Sections are placed on the ground by crane and further disassembled into shippable parts.

Form Travellers vs. Traditional Construction

The main advantage of form travellers over other construction methods is that they allow for longer and wider spans to be built in challenging site conditions. Form travellers are better suited for bridge designs involving fewer piers because they can span much greater distances than other methods. This chart generically summarizes the maximum spans, widths, and timelines allowed by various concrete bridge construction techniques.

Moving Scaffolding Systems (MSS)

Moving scaffolding systems (MSS) cannot take full advantage of cantilevered construction techniques as compared to form travellers. Customized (expensive) MSS equipment is required for bridge decks greater than 20 m (approx. 65'). Moving scaffolding systems can be more cost-effective for long bridges with equal repeated spans (or multiple spans) because it is generally a quicker method: 30–60 m (approx. 98–196') span every week, or 60–90 m (approx. 196–295') span every two weeks. For bridge decks with a substantial turn radius, the MSS become less easy to operate. The MSS structure has to extend outward and move around constructed bridge piers as shown in this video .

Incremental Launching

Incremental launching is preferred for long straight bridge spans or those with a large and constant turn radius. This method becomes less feasible when the design requires an angled bridge deck relative to the horizon or a flat deck with a varying turn radius. The placement of each span increment is limited by the size of the hydraulic system pushing each span segment into place. Initial installation costs of the launching equipment (cables, hydraulics, rollers, etc.) is high, generally becoming more cost-effective as total bridge lengths approach 400 m (approx. 1,312'). It is usually good for small wide bridge decks that can be built in consistent segments, such as railroad bridges. It is also a good option in places where the bridge is high because the contractor doesn't need to use cranes or transports along the bridge to place deck segments. Concrete and steel materials are staged at a consistent location, so the system works similarly to a production factory.

Pre-Cast Materials

Pre-cast construction is often not suitable for larger spans. The length of the pre-cast concrete members is limited by factory equipment, the behavior of formed concrete, and shipping considerations. The use of pre-cast members is not feasible in some remote areas due to poor access roads. Transporting and elevating pre-cast members with cranes can be particularly challenging for bridge projects with poor access, rivers, or low support conditions. The higher a project’s bridge piers, the higher the cost of crane operations (i.e., larger crane equipment is required).

Heavy Propping and Traditional Scaffold Formwork

When the bridge spans are located at significant heights above grade, traditional formwork becomes no longer feasible since it requires bracing to ground. It becomes more labor-intensive and tedious as span lengths and pier heights increase. ConstruGomes has used heavy propped formwork up to only 40 m (approx. 131') of bridge span and height. These systems are normally limited to a height of 40 m because of material limitations and safety considerations. The spans can be large because they can have multiple support towers on the ground. The limit of 40 m of span is between a set of propping towers only.

Self-Climbing Formwork

Self-climbing formwork operates similarly to form travellers but builds piers vertically in increments as opposed to bridge decks laterally. Self-climbing formwork is installed at grade and can be used to construct the entire height of a new cast-in-place concrete pier. Lifts of up to 5 m (approx. 15') every 2–3 days can be achieved. Self-climbing formwork needs a constructed pier height of only 1 m (approx. 3') to begin operations.

Image Gallery

This image gallery below of ConstruGomes projects in the Marao Mountains and the Azores highlights their use of form travellers and self-climbing formwork in state-of-the-art bridge construction.

Like this article? Sign up for our monthly newsletter and get the latest updates!

Andrew Kimos

Andrew Kimos completed the civil engineering programs at the U.S. Coast Guard Academy (B.S. 1987) and the University of Illinois (M.S. 1992) and is a registered Professional Engineer in the state of Wisconsin. He served as a design engineer, construction project manager, facilities engineer, and executive leader in the Coast Guard for over 20 years. He worked as a regional airline pilot in the western U.S. before joining the Buildipedia.com team as Operations Channel Producer.

Latest from Andrew Kimos

- Case Study: Water Quality Retrofit and Retaining Wall Remediation

- Construction Documents Technology Proves Cost-Effective

- In-Situ Pipe Repairs Save Time and Money

- In Situ Pipe Repairs Save Time and Money

- U.S. Infrastructure: Drinking Water

At Home Topics

- Everyday DIY with Jeff Wilson

- 60 Simple Seconds

- Jeff Wilson Everyday DIY Blog

- Rehabitat with Rachael Ranney

- Design & Remodeling

- Landscaping

- HVAC | Electrical | Plumbing

- Walls | Windows | Doors

AEC Pros Topics

- Featured Architecture

- Design News

- Solar Decathlon

- Construction Materials & Methods

- From the Job Site

- Engineering News

- Public Infrastructure

- Facilities Ops & Maintenance

- Urban Planning

- CSI Project Solutions

Knowledgebase

- Division 02 Existing Conditions

- Division 03 Concrete

- Division 04 Masonry

- Division 05 Metals

- Division 06 Wood, Plastics, and Composites

- Division 07 Thermal and Moisture Protection

- Division 08 Openings

- Division 09 Finishes

- Division 10 Specialties

- Division 11 Equipment

- Division 12 Furnishings

- Division 13 Special Construction

- Division 14 Conveying Equipment

- Division 21 Fire Suppression

- Division 22 Plumbing

- Division 23 HVAC

- Division 26 Electrical

- Division 27 Communications

- Division 28 Electronics Safety and Security

- Division 31 Earthwork

- Division 32 Exterior Improvements

- Division 33 Utilities

- Find Us on Twitter

- Find Us on Facebook

- Find Us on YouTube

- Find Us on Pinterest

- Editorial Calendar

- Advertising

- Writers Guidelines

- Terms and Conditions

- Construction Calculator: Simplified Construction Cost Calculator

- Members Login

What Is Form Traveler In Construction?

- Building & Construction

A form traveller is a type of travelling formwork system used in bridge construction. It enables the repeated construction of structural elements and is typically used for free cantilever construction of post-tensioned box girder and cable-stayed concrete bridges.

Form travellers are supported by the part of the structure already built, and can be overhead or underslung

Form traveller is a system used for free cantilever construction of post-tensioned box girder and cable-stayed concrete bridges. It is lightweight, versatile, easy to assemble and operate, rolling forward on rails or rollers, and supports the weight of the construction elements including formwork, traveler, reinforcement and uncured concrete.

The form traveller system is designed to be highly stable and rigid so that it does not move significantly under the weight of the concrete as it is poured or during curing. It also has features such as being portable and cost effective.

The Standard form traveller is intended to be used for bridge construction and has a maximum segment length of 5 meters. The load capacities for concrete and formwork can range from 250 to 400 tonnes. The weight of the steel used in the form traveller depends on the specific cross-section of the bridge, typically ranging from 25 to 65 tonnes.

It is possible to modify the Standard form traveller to fit almost any cross-section and adjust it during use to accommodate changes in segment length, section height, web thickness, and deck width.

What Is Form Traveler Used For?

Form travellers are used for free cantilever construction of post-tensioned box girder and cable-stayed concrete bridges. They are lightweight, versatile, easy to assemble and operate, rolling forward on rails or rollers, and offer significant cost savings over traditional methods.

Form travellers are preferred for building spans over deep valleys, waterways, and roads where access from the ground is a challenge and the number of piers is limited.

The main advantage of form travellers over other construction methods is that they allow for longer and wider spans to be built with less material than traditional methods.

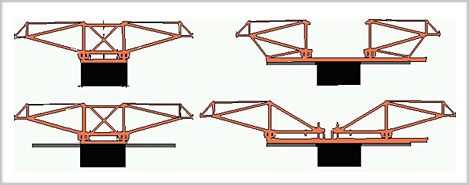

Form travellers come in two types: overhead form travelers which are suspended underneath the bridge structure already erected, and under-slung form travelers which are mounted on top of the structure already erected.

Is Form Traveler Used For Construction Of Superstructure?

Form travelers are commonly used for the construction of cantilever segmental bridges, as they provide a convenient and efficient means to build superstructures.

These form travelers give shape to the segment, support the weight of the newly cast concrete until it has gained enough strength to be post-tensioned to the previous cantilever segments, and transfer the segment weight to the already existing superstructure.

Form travelers can also be used in certain circumstances for other types of bridge structures (such as truss or arch bridges), depending on the specific design requirements.

Form Traveller Installation

Installation of form traveller involves assembling the equipment on the ground and lifting segments by crane to their starting points on a specific bridge pier.

Form travellers come in two main types: overhead and underslung, with both being designed for free cantilever construction of pre-stressed girder and cable–stayed concrete bridges.

Structural analysis is used to improve the performance and alignment of bridges, as well as ensure that the formwork does not move significantly under the weight of the concrete during pouring or curing.

Form Traveller Components

Form traveler components consist of a main frame, walking and anchoring device, bottom mould frame, side mould frame, inner mould frame, front lifting device and rear lifting device which are important for the smooth functioning of form travelers.

The main frame provides stability to the whole assembly while the walking and anchoring devices assist in its movement. The mould frames form an enclosure for supporting the form structure pieces and the lifting devices on both ends help in moving them between different levels.

Related Posts

What is an electroless plating.

What Is An Electroless Plating? Electroless plating, also known as chemical plating or autocatalytic plating, is a method of creating a metal coating on a variety of materials through the use of a chemical bath that reduces metal cations. This process differs from electroplating, in which an electric current is used to create the metal […]

What Is Exterior Insulated Finishing System?

What Is Exterior Insulated Finishing System? Exterior Insulated Finishing System (EIFS) is a non-load bearing building cladding system that provides exterior walls with an insulated, water-resistant, finished surface in an integrated composite material system. EIFS has been in use since the 1960s in North America, and was first used on masonry buildings. Since the 1990s, […]

What Is A Facing Tool In Metalwork?

What Is A Facing Tool In Metalwork? A facing tool is an important tool in metalwork that is mounted into a tool holder and placed onto the carriage of the lathe, allowing the user to cut away material from the outer surface of a rotating piece. Facing tools feed perpendicularly across a part’s rotational axis […]

BRIDGEBUILDER FORMTRAVELLER

Travelling formwork system for free cantilever construction.

BRIDGEBUILDER Enhance The Economic Performance of Bridge Projects.

Reliable Bridge Construction Equipment for Free Cantilever Construction with NRS Innovation and Solutions.

“BRIDGEBUILDER” FORMTRAVELLER

The Overhead and Underlane NRS Formtraveller which is widely and well known as the Bridgebuilder, is the most reliable and extensively used FormTraveller system in the world for in-situ construction of free cantilever post tensioned box girder bridges as well as cable-stayed concrete bridges.

It has been adopted as the de facto design that is widely used among all suppliers in the industry.

To date NRS has supplied more than 1000 units of Bridgebuilder worldwide.

The “Bridgebuilder” formtraveller system was invented in 1970 and today it is acclaimed for enhancing the cost-effectiveness of bridge projects worldwide.

The Bridgebuilder has undergone vast improvements over the years and incorporated innovative solutions, making it a developed, practical and reliable system for contractors.

Today the Bridgebuilder is a versatile, lightweight, easy-to-assemble and operate.

The system is designed with the following cost savings solutions:

- Special “Fast-Split” installation method on hammerhead as short as 7m long.

- NRS Bridgebuilder with cross member for Hammerheads as short as 3m.

- Back launching to pier for ease of dismantling after use

- Use of Bridgebuilder for casting hammerhead

- Casting closure segment stitches.

STANDARD CONVERTIBLE BRIDGEBUILDER

The Standard Bridgebuilder is designed for a maximum segment length of 5 m and load capacities (concrete and formwork) varying from 100 tons to 400 tons. The steel weight depends on the cross-section of the bridge in question, but will normally vary from about 25 tons to 65 tons correspondingly. The Standard Bridgebuilder may be adapted to suit almost any cross-section, and is easily adjustable during operation to variations in segment length (up to 5 m), section height, web thickness, and deck width.

TAILORED BRIDGEBUILDERS

The Bridgebuilder may be tailor-made for segment lengths beyond 5 m and other extreme conditions. Alternatively it may be designed for shorter lengths where the maximum segment length is less than 5 m, and there is a requirement to reduce the weight of the Bridgebuilder for a particular application.

NRS Special Bridgebuilder for arch bridge construction has also been used successfully for the construction of the 323m arch bridge at the Hoover Dam Bypass project – the longest arch bridge in North America and the 4 th longest concrete arch bridge span in the world.

Modern bridges are becoming wider and longer but at the same time clients and contractors are seeking shorter construction time. In NRS, pursuing improved and innovative solutions to meet these requirements has always been one of NRS main goals.

NRS never fails in giving innovative designs even for conventional equipment like the Formtraveller

THE BRIDGEBUILDER FEATURES

- Lightweight

The use of rectangular hollow sections in the main structural components and recoverable high strength bars in all stays and ties reduces the total steel weight to a minimum.

- Versatile and Flexible Design

The Bridgebuilder may be adapted to almost any cross-section and is easily adjustable during operation to variations in segment length, box height, web thickness, deck width and road alignment (gradient, curvature, super-elevations).

- Small Deflections

The vertical deflection at the front of the Bridgebuilder is less than 25 mm at maximum load. Formwork beams are designed for a maximum deflection of 1/400 of their length.

- Easy Assembly and Operate

-One Bridgebuilder may be assembled in one week. Rolling forward on rails, the reset time is short.

-Lifting system to lift and install the whole Bottom slab for Overhead BB FT and the whole pre-assembled on ground Underlane BB FT.

– Rebar Carrier and trolley system

SPECIFIC DETAILS

Technical principle & working cycle.

A normal working cycle may be as follows:

- The Bridgebuilder, except for the internal formwork, is launched into position for a new segment

- The external formwork is levelled and fixed.

- Bottom slab and webs reinforced.

- The internal forwork is pulled forward.

- Concreting of bottom slab and webs. The top slab may be cast after a short intermission to allow setting of the concrete in the webs, or it may be cast the next day.

- After sufficient concrete curing, post-tensioning takes place.

- Form work is loosened, and the Bridgebuilder launched forward to the next segment. In most cases one cycle is carried out in one week. There are examples of 4-5 days cycle.

MAIN PRINCIPLE & COMPONENTS

Cross-Member For Installation On Small Pierheads

When the pier head is too small to allow normal assembly of the Bridgebuilder, our patented Cross-member solves the problem. It makes it possible to start free cantilevering from pier heads as small as 3 m. The procedure is illustrated through the above 4 phases.

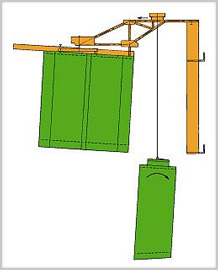

Precast Segmental Bridgebuilder

The Precast Segmental Bridgebuilder is equipped with two hoists for lifting the precast segments as well as for adjusting the crossfall. A manipulator permits adjustment of the longitudinal fall and hydraulic cylinders launch the device forward.

The World's 10 Longest Free Cantilever Concrete Bridges

Some of the world’s most outstanding bridges have been built by use of the NRS Bridgebuilder Formtraveler. Refer to the table below.

OH-BB FT TRYSFJORD BRIDGE, NORWAY

UL BB FT YEONGGWANG – HAEJE BRIDGE, KOREA

OH BB FT Gabrovo, Bulgaria

Underslung Form Traveller

- Design, fabrication, delivery and technical assistance to the new equipment

What Is Underslung Form Traveller

The Underslung Form Traveller solution can be adapted to different types of bridge decks, such as arch bridges and cable-stayed bridges, leaving enough room to assemble the temporary or final cable stays, and allowing easy launch-back to the initial assembly position.

Safe, Typical, Adjustable

A standard underslung Form Traveller is designed for a segment length of 5 m. It can be tailor made for various segment lengths.

MIDAS software calculation

When the rebar cage is preassembled, the Underslung Form Traveller is the perfect choice.

Save Cost to Be Reused

The external formwork of this type of Form Traveller is supported by the main structure, leaving enough room to install the preassembled rebar cage.

Pre-test and Pre-load

Systems are easy to use even by persons who have never worked with it.

Expert at This Area

Our service.

- Tender stage quotation preparation

- Rebuilt design regarding existing equipments delivered by us, for use in different conditions of the original

Send a Message

Your contact to ohc.

Address: 195, E. 4th Ring Rd Middle, Chaoyang District, Beijing, 100124, China

Phone: +86 13941265037

Thank you for your interest in OHC Formwork. To help us promptly meet your request, please Send a Message, Email, or Call Us, Follow Us.

- Organisation

- Project management

- Sustainability

- Code of Conduct

- Report anonymously

- Residential & commercial high-rise construction

- Power Plants

- All references

- All products and services

- Safety with Doka

- Fair-faced concrete

- Training in Germany

Digital Services

News & updates.

- Tradeshows & dates for your calendar

- Careers at Doka

- Career options

- Current job vacancies

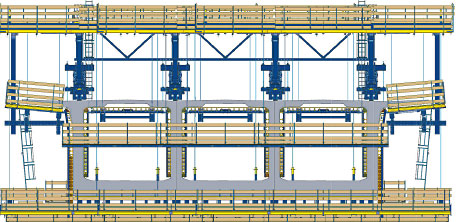

Cantilever forming traveller

Formwork and shoring from one single supplier

The Doka cantilever forming traveller provides certainty regarding planning and costs while ensuring an optimum construction workflow. The perfect design match between the CFT's shoring structure and the formwork, its high standard of safety and its optimised workplace-ergonomic design together ensure that work can progress swiftly and safely.

Reduced costs

From having a rentable and precisely co-ordinated all-in-one solution .

- because the equipment is rentable, it does not need to be pre-financed

- the small number of separate parts keeps site-erection times short

- easy-to-understand, ergonomically engineered system makes for fast repositioning and cycle times

- its modular components help it adapt flexibly to different geometries

Smooth project progress

Because of the detailed co-ordination between the cft and the formwork .

- the all-in-one, single-sourced package means there are fewer interfaces to the superstructure designer

- project-specific Operating Instructions describe all worksteps in detail

- short delivery times thanks to rapid availability of standard system components

- time-savings thanks to ongoing support from experienced Doka Formwork Instructors

Safety at all times

In every phase of the work .

- fully railed-in working platforms on all levels

- the CFT's anchorages are hydraulically test-loaded before every pour

- slide bearings secure the CFT against unwanted travelling on longitudinal gradients

Corridor Vc, bridges at Studenčica and Trebižat

Inn-bridge Ehring

Budowa Autostrady A4, obiekt E-118

Brug over Amsterdam-Rijnkanaal

Bridge Road 4 to 20 - Israel

Tverlandsbrua - Norway

Bridge over the River Elbe

Seidewitztalbrücke A17

Bridge over River Main, Ochsenfurt

Arad Bypass

Bridge near Teror

Bridge over Rhine in Basle

Tisza Bridge

Danube bridge at Traismauer

Bridge over the River Vltava

Optimised longitudinal trusses

- ergonomically designed, with upward-extended longitudinal trusses for more headroom

- horizontal pre-assembly, incl. of ladder system and catwalk, is possible

Universal anchoring cross-beam

- the suspension rods can be flexibly positioned for adaptability to different bridge geometries

- asymmetrical cross-beam configurations are possible where space is constricted due to e.g. neighbouring structures

- broad working platform from which the suspension rods can be operated safely

- pre-assembly is possible, incl. of platform

Modular design concept

The longitudinal trusses can be variably positioned, which makes it easy to adapt the cantilever forming traveller to variable-width or multi-cell cross-sections.

Pre-assembled platform system

- on all work-deck levels

- with integrated ladderways complete with ladder cages and self-locking manholes

- generously sized workplace access routes for safe, efficient working

Innovative drive unit

- permanent self-locking safety feature using slide bearings to guard against unwanted travelling, effective up to a longitudinal gradient of six percent

- incorrect operation of this safety feature is impossible, as it is always active

Bracing located on outside

- makes it easier and quicker to place reinforcement steel and concrete, by permitting unobstructed access from above

Suitable products

Edge protection system XP

Doka safety systems.

This system is the universal safety solution for all edge protection needs. It fits in ideally with …

Guard rails

These tried-and-tested systems give your site crew optimum protection and make a significant contrib…

Ladder system XS

System-based ladderways with integral ladder cages can be attached to Doka wall and column formwork …

Application Videos

Documents & Downloads

No results found.

Show further documents of this product group

pd overlay headline pd overlay subline

News & Updates

Thank you for your interest - cantilever forming traveller., please, fill in the form below to receive more information on this topic and access it conveniently from your email later..

All listed fields are required. By using our site, necessary cookies are set on your device for the execution of the service. Find out more in our data privacy policy https://www.doka.com/data-privacy .

Thank you very much for your interest - Cantilever forming traveller.

A link with further information has been sent to the provided e-mail address..

You can now switch back to the QR code reader to request information on other topics. You have the option to save your contact details to be automatically used for your next request.

Free cantilever method

- Certificates

This method of constructing a bridge structure is used mainly for bridges spanning deep valleys or for inaccessible terrain. An optimal span suitable for free cantilevering is 60 m – 150 m, but bridges with a considerably larger span are commonly realised.

The free cantilever technology consists in developing the bridge structure by individual parts, the so-called segments. Segments are concreted into formwork fixed to a special movable steel structure – form traveller. An optimal design and weight of the form traveller is fundamental for the design and economic advantageousness of the given structure.

VSL offers the so-called modular system of form travellers, which can be applied to bridge structures with different cross-sections and lengths of segments. The lightweight system of VSL form travellers has minimal demands on lifting equipment at installation at the beginning of construction and enables at the same time an easy access to all work fronts during the construction. The typical working cycle takes five days with 12-hour shifts and with the construction crew alternating in two form travellers. In case of need, the form traveller may be equipped with a system for steam curing, which reduces the working cycle to four days.

Welcome to the official website of Nantes Crane, the world leading Cranes and Crane Components Service Provider.

Form Traveller

Product Description

The form traveler (Called Bridge Builder) is common equipment for the construction of large-span pre-stress bridges which use cast-in build method. It can be used to build the segment one section by one section without supports and the help of large cranes.

The form traveler is a load-bearing frame that can slide or roll along the top of the bridge deck. It is anchored and suspended on the constructed beam section. The form traveler can be used for the installation of the next beam section’s formwork, reinforcement, pre-stressed pipes, concrete pouring, pre-stress tensioning, grouting and other operations. After completing the cycle of one segment, the form traveler can move forward and fixed to carry out the suspension grouting of the next segment, and so on until the cantilever grouting is completed.

Technical Parameter

Application areas

Bridge Construction

Highway & High Speed Railway Construction

Metro Rail Transit Construction

Shaoxing Nante Crane Equipment Co., Ltd.

Lianxing Village, Dongguan Street,Shangyu District, Shaoxing City

+86 575-81260826

Get In Touch With Us

2022 © NANTECRANE . All rights reserved. Shaoxing Nante Crane Equipment Co., Ltd. Privacy Policy

Overhead Form Traveller/ Bridge Builder - BECT Ltd

- BECT Ltd - ABOUT US

- DESIGN & CONSULTANCY

- CONSTRUCTION ENGINEERING

- Construction Equipment

- Underslung Form Traveller

- Overhead Form Traveller

- Underslung System

- Overhead System

- Underslung LG

- Overhead LG

- Beam Launcher (BL)

- Segment Lifter (SL)

- Overhead FT Components

- Underslung FT Components

- Overhead FT Operation

- Special Arrangement System

8618513399356

- About Us Company Profile Production Patents Certificates Awards

- Products Form Traveler Segmental Box Girder Formwork T/I/U Girder Formwork Pier Formwork Tunnel Lining Trolley

- Services R&D Capability IUR Cooperation Design Support On-site Services

- Project Cases Form Traveler Cases Segmental Box Girder Cases T/I/U Girder Formwork Cases Pier Formwork Cases Tunnel Lining Trolley Cases

- Cooperation Cooperation Modes Rental Business Agency

- News & Blogs News Blogs

- Contact Us Contact Information Catalog and Brochure Technical Documentation Video View

- Cantilever Form Traveler

- Underslung Form Traveler

- Asynchronous Form Traveler

- Light Form Traveler

- Segmental Box Girder Formwork

- T/I/U Girder Formwork

- Pier Formwork

Tunnel Lining Trolley

Cantilever Form Traveler with Main Span Below 150 Meters

Product details, product description.

Cantilever form traveler with main span below 150 meters refers to the form traveler applicable to bridges with main span below 150 meters. Scope of application:The cantilever form traveler with main span below 150 meters is suitable for the construction of small and medium-span bridges, including highway bridges, railroad bridges and municipal bridges.

Applications

Chongping Railway Extra Large Bridge

Main Span 80 Meters

Kunlun Bridge

Main span 100 meters

Hanshounan No1 Super BridgeB

For more case information ↑

1. It has a compact structure and high carrying capacity, and can adapt to the construction needs of small and medium-span bridges.

2. The form traveler has good stiffness and stability, which can ensure safety and stability during the construction process.

We offer on site consultation and safety advice to help our customers work safely and improve productivity in each project.

The Boyoun Technical Office combines its staff experience with advanced CAD systems and self-developed software to do this job.

Q1: What is the load-bearing capacity of a cantilever form traveler with a main span of less than 150 meters?

The load-bearing capacity of cantilever form traveler with a main span of less than 150 meters will vary according to different specifications and designs. Generally speaking, its load-bearing capacity ranges from several tons to tens of tons. The specific load-bearing capacity needs to be determined based on actual construction requirements and design calculations of the form traveler.

Send your message to this supplier

Successful cases.

Thailand Lopburi Railway Cantilever Form Traveller Case

Cantilever Form Traveler Project for the Lu River Expressway Bridge in Lilou

Jitong Railway Duolun River Bridge Project

You may also like……

Single Box Single Cell Segmental Box Girder Formwork

Precast U Girder Formwork

Precast T Girder Formwork

Single Box Single Cell Cantilever Form Traveler

Single Box Double Cells Cantilever Form Traveler

Single Box Multiple Cells Cantilever Form Traveler

We focus on turn-key solutions and types of formwork for Bridge and Viaduct Construction at home and abroad since 2006.

Quick Links

- Project Cases

- Cooperation

- News & Blogs

Get In Touch

International Department: Room 2211-2212, Tower C of Wanda Plaza, Tongzhou District, Beijing 101118, China.

+86-13021287080

Form Traveler

- Share full article

Advertisement

Supported by

Making Art From the Unexpected at Milan Design Week

Designers are showing off some of their latest works at the annual festival of furnishings and household objects.

By The New York Times

This article is part of our Design special report previewing Milan Design Week.

Designers are by definition manipulators — of materials, senses and expectations. There is nothing they like better than making the beholders of their creations stop in their tracks. At the Salone del Mobile, in a show devoted to emerging designers that runs through Sunday, visitors may be arrested by a cushion that resembles a big colorful, softball and sits like an egg in a nest of polished wood sticks. What is it? An ottoman, naturally. A few other eye catchers and head scratchers are presented below.

Another Approach to Seating

After studying industrial design at the University of Notre Dame, Ryan Twardzik tried his hand at footwear, accessory and graphic design. But “all I wanted to do was furniture,” he recalled. Moving to Schuylkill County, in Pennsylvania, in 2021, he had access to local manufacturers, including a metal fabricator who primarily built roller coasters. That led to his furniture company, Unform Studio, and its debut collection, Drip, a series of fluoro-colored chairs formed of bent metal sheeting. “I want to make things that are not just fun to look at, but also fun to touch and interact with,” he said.

Mr. Twardzik is showing works from two new collections at SaloneSatellite, the presentation of young designers that runs concurrently with the Salone del Mobile. The first, Spherae, is a ball-shaped cushion supported by three polished wood dowels that slide through a brass disc and lock into place.

“I’ve been calling it passive joinery,” Mr. Twardzik said, because the construction, inspired by foldable camping chairs, does not require tools for assembly. The stool or ottoman comes with four different cushions resembling giant, fruit-toned softballs that can be swapped out. “You can just pop whichever color you want on there,” he said, “and the other three live around the piece.”

The designer is also showing an armchair from his Pop-Up collection. Formed of 20 metal posts wrapped in upholstered foam cylinders, it functions loosely like a soft-touch bed of nails. “They pop up at different heights. Some to arm and back height and some to a shorter seat height,” he said about the components. The experiments, he added, are far from over: “There are so many ways to explore how to make a chair.”

On view Tuesday through Sunday at Salone del Mobile, Pavilion 5, Booth C17; unformstudio.com . — LAURA MAY TODD

Exploring the Sound of Color

Last year at peak times, visitors to “Shaped by Water” — Google’s Milan Design Week offering — stood in line for up to two and a half hours to be admitted.

Inside the exhibition, they experienced light and sound waves passing through water in humming, resonant bowls (some visitors started hugging them), and a planetarium-style music and light show. “We had some people coming back three and four times,” said Ivy Ross, Google’s vice president of hardware design, who oversaw the project.

Now Google is switching elements with a celebration of color, partnering with the California arts and research lab Chromasonic to create the installation “Making Sense of Color.”

Thanks to Chromasonic’s technology, which translates light waves into sound and sound waves into light, visitors who pass through “Sensory Field” — 21 spaces at the beginning of the installation separated by translucent scrims — are able to “hear” the visible spectrum, in the form of shifting melodic tones.

Johannes Girardoni, a founder of Chromasonic, said this experience creates “an atmosphere in which physical space appears infinite, at other times enveloping.”

Elsewhere in the exhibition the design team has unpacked how color feels and what it tastes and smells like. The final space presents a tableau of Google products in different colors, like the Google Pixel Watch 2 and the Pixel phone.

“It’s kind of a reveal that brings it all together,” Ms. Ross said.

She added that she hopes visitors will gain a new appreciation for color’s many dimensions. “After having the experience of what does it sound like, feel like, taste like, look like,” she said, “they’ll never look at color the same way.”

On view Tuesday through Sunday at Garage 21, Via Archimede, 26. — MEGAN McCREA

Let There Be Light

The lighting designer Volker Haug and his team have partnered with the architects at Flack Studio to create Me and You, 13 decorative lighting fixtures that have nothing to do with a dog named Boo .

The collaboration between studios, both in Melbourne, Australia, grew out of a mishap. Last year, a vintage wall sconce was being installed in a private residence designed by Flack Studio when the glass broke. Replacing the lamp meant refinishing the wall behind it, and there was no time for that. So David Flack, the firm’s founder, asked Mr. Haug, a longtime acquaintance, to create a new sconce for the square metal wall plate that was already in place.

The success of the ad hoc solution “inspired us to go, ‘Ooh, what else could we do?’” Mr. Haug recalled in a phone call from Melbourne.

The men began knocking out other ideas for lamps based on metal squares, but soon their designs “started getting longer and skinnier, or smaller or rounder,” Mr. Haug said.

The lamp called Bruce is closer to the original conception. First designed by Flack Studio for the Ace Hotel in Sydney, it was revised by the collaborators as a boxy, cast-brass grid laid over textured, glowing glass, which gives it some opacity, “like a bathroom window,” Mr. Haug said. A linear version — a single row of squares — has just been added to the collection.

Me and You can be seen Tuesday through Sunday at Via San Maurilio, 18; volkerhaug.com and flack.studio . — JULIE LASKY

Using Older Spaces for New Talent

Lionel Jadot, a Belgian designer and architect, is partial to retrofitting old manufacturing buildings. His own company, Zaventem Ateliers, occupies a 6,000-square-meter (64,583 square foot) 19th-century paper factory near Brussels. During Milan Design Week he is again transforming a run-down industrial site into a showcase for young talent.

He has organized a display of furniture, lighting, textiles and sculpture by more than 30 designers, studios and artists — mostly from Belgium but also a handful from other countries. All these works are presented in this year’s new location, a 7,300-square-meter (78,577-square-foot) 1950s industrial building near Milan’s Linate Airport, under the name Baranzate Ateliers, its second appearance at Design Week.

“I’m part of a family of makers since six generations,” Mr. Jadot said. “I know what a struggle it is to be in your workshop, to try to produce, to try to connect with people, to create collaboration.”

Many of the pieces straddle the line between furniture and sculpture. Mircea Anghel, a designer in Lisbon, makes tables and chairs from rough stones and polished wood. Studio Élémentaires in Belgium combines bits of the urban fabric (aluminum, motors, reflective filters) with LEDs to create kinetic lighting. KRJST Studio in Belgium weaves tapestries with “the monstrous creatures that haunt our dreams, not as external threats, but rather as mirrors of our own dark side,” said Justine de Moriamé, a founder with Erika Schillebeeckx of the studio, which is displaying examples of such work, including the hanging called Kappa.

The tapestries are inspired by the phenomenon of pareidolia, or the tendency to see shapes or make pictures out of randomness. “It is these harmonious or chaotic reveries that form the basis of our imaginations and personal mythologies,” Ms. Schillebeeckx added.

Baranzate Ateliers is on view Monday through Sunday at Via Gaudenzio Fantoli 16/3; baranzateateliers.com . — STEPHEN TREFFINGER

An earlier version of this article misstated the location of the Baranzate Ateliers exhibition during Milan Design Week. It is in an industrial building near Milan’s Linate Airport, not in the Baranzate municipality northwest of central Milan.

How we handle corrections

Explore Our Style Coverage

The latest in fashion, trends, love and more..

An Unusual Path to Hollywood: Sobhita Dhulipala has taken on risky roles in her acting career, outside of India’s blockbuster hits . Now, she’s starring in Dev Patel’s “Monkey Man.”

These Scientists Rock, Literally: The Pasteur Institute in Paris, known for its world-altering scientific research , has been making advancements in another field: the musical arts.

JoJo Siwa Grows Up: Siwa, the child star turned children’s entertainer, who at first modeled her career on Hannah Montana, is now after her own Miley (Cyrus) moment .

Jill Biden Makes an Entrance: The first lady was glittering in crystals — days after Melania Trump stepped out in pink at a Palm Beach fund-raiser. Together, the pictures offer a harbinger of what is to come .

Creating Works of Ephemeral Beauty: A YouTube rabbit hole led Blanka Amezkua to a small Mexican town and the centuries-old craft of papel picado — chiseling intricate patterns into colorful paper flags.

New York Bridal Fashion Week: Reimagined classic silhouettes, a play on textures and interactive presentations brought fresh takes to the spring and summer 2025 bridal collections.

- FINANCIAL SERVICES HOME

Search form

- News & Events

Employee Travel and Reimbursement Fiscal Year End Updates FY 2024

Employee Travel and Reimbursement (ET&R) has included updates for the 2024 fiscal year-end process. Please use the information below as a reference for the fiscal year-end schedule related to out-of-pocket reimbursements, corporate card charges, and experimental subject payment forms.

Out of Pocket Expenses*

Both electronic and paper reimbursement forms must be submitted, approved, and received in ET&R by the end of the day on Monday, June 17, 2024, to be posted in the current fiscal year.

Experimental Subject Payment Forms*

Experimental Subject Payment forms must be received in ET&R by 5:00 pm on Monday, June 17, 2024, to be posted in the current fiscal year.

*NOTE : all reimbursement forms/expense reports are due to ET&R by 5:00 pm on Monday, June 17, 2024. This is a change from prior fiscal years.

Corporate Card Transactions – Concur

- All expense reports received in ET&R by the end of the day on Monday, June 17, 2024, will be processed in fiscal year 2024.

- 695685 - Unapproved Corporate Card Transactions; Assigned corporate card expenses without complete approval.

- 695695 - Unassigned Corporate Card Transactions; Unassigned corporate card expenses with no action taken.

- ET&R will send Untimely Posting Notification emails for transactions through May 15 beginning Wednesday, May 22 through Wednesday, June 12, 2024.

- Employee Travel & Reimbursement will stop posting transactions for fiscal year 2024 on Monday, July 8, 2024. We will send a complete list of Assigned and Unassigned transactions to Business Managers and Management Centers on Tuesday morning, July 9, 2024. This will allow time for departments to review the outstanding corporate card charges and process accruals per their management center guidelines. ET&R will not process an accrual of corporate card charges for fiscal year 2024.

► Deadlines for departments that are using the WORKS system for FLEET and other applicable programs will be communicated by the Card Services team.

We appreciate your continued support. If you have questions, please contact a member of our team at 668-3877 or via email at [email protected] .

IMAGES

VIDEO

COMMENTS

Form travellers are better suited for bridge designs involving fewer piers because they can span much greater distances than other methods. This chart generically summarizes the maximum spans, widths, and timelines allowed by various concrete bridge construction techniques. Form Travellers. Moving Scaffolding Systems (MSS) Incremental Launching.

A form traveller is a type of travelling formwork system used in bridge construction. It enables the repeated construction of structural elements and is typically used for free cantilever construction of post-tensioned box girder and cable-stayed concrete bridges. Form travellers are supported by the part of the structure already built, and can ...

The overall bearing capacity of the form traveler meets the design requirements, and the improvement of the form traveler is effective. Ye-Lang Lake Bridge was opened to traffic successfully on August 31st, 2018. The maximum difference between the measured value and the theoretical value of the arch ring alignment is only 25 mm, which meets the ...

The Standard Bridgebuilder is designed for a maximum segment length of 5 m and load capacities (concrete and formwork) varying from 100 tons to 400 tons. The steel weight depends on the cross-section of the bridge in question, but will normally vary from about 25 tons to 65 tons correspondingly. The Standard Bridgebuilder may be adapted to suit ...

If you are looking for balanced cantilever bridge construction methods for form travelers, then this video is for you! In this video, we walk you through the...

Design, fabrication, delivery and technical assistance to the new equipment. Rebuilt design regarding existing equipments delivered by us, for use in different conditions of the original. form traveller is a temporary support structure supporting the weigh of the bridge and viaduct deck segments cast in situ.

The underslung Form Traveller system can be adapted to different types of bridges, such as arch and cable stayed structures, leaving no obstructions to temporary or permanent cables. A standard underslung Form Traveller is designed for a segment length of 5 m. It can be tailor made for various segment lengths.

A form traveler used in bridge construction has a great influence on the safety of the performance and alignment of bridges. As a cantilever casting segment of a bridge becomes longer and heavier ...

The Strukturas as Form Traveller (FT) system is a competitive and reliable solution for balanced cantilever construction method. With our 50 years of experience in conception and designing bridge ...

fully railed-in working platforms on all levels. integrated ladders, complete with ladder-cages. the safety feature which self-locks the CFT while it is being advanced on sliding plates. With the newly developed cantilever forming traveler, the 20 ft. long deck segments of the Viaducto de Teror are being cast in a weekly cycle.

The Underslung Form Traveller solution can be adapted to different types of bridge decks, such as arch bridges and cable-stayed bridges, leaving enough room to assemble the temporary or final cable stays, and allowing easy launch-back to the initial assembly position. ... Rebuilt design regarding existing equipments delivered by us, for use in ...

The Doka cantilever forming traveller provides certainty regarding planning and costs while ensuring an optimum construction workflow. The perfect design match between the CFT's shoring structure and the formwork, its high standard of safety and its optimised workplace-ergonomic design together ensure that work can progress swiftly and safely.

An optimal design and weight of the form traveller is fundamental for the design and economic advantageousness of the given structure. VSL offers the so-called modular system of form travellers, which can be applied to bridge structures with different cross-sections and lengths of segments. The lightweight system of VSL form travellers has ...

Form Traveller. SDI FT is a cost - effective and reliable solution! Both the overhead and the underslung FT are designed for free cantilever construction of pre-stressed girder and cable - stayed concrete bridges. A standard underslung FT is designed for a segment length of 5 m. It can be tailor made for various segment lengths.

The form traveler (Called Bridge Builder) is common equipment for the construction of large-span pre-stress bridges which use cast-in build method. ... Nante's form traveler is modulated design and connection, can be modified and repeat use for different site. Technical Parameter. Type: Capacity: Trigonometric Form Traveler: 50t-150t: Diamond ...

form traveler and the wet weight of the concrete is assumed by the anchor suspender.24-32 The main per-formance parameters of the new form traveler are shown in Table 1. Compared with the traditional form traveler in can-tilever cast reinforced concrete arch bridge, the new form traveler (as shown in Figure 3) has many advan-

Form-Traveller whether Overhead or Underslung Model is usually used for cast-in-situ bridges constructed by a balanced cantilever method. The overhead model is more common and easier to use compared with the Underslung Model. The Underslung Model becomes superior when construction clearance over the formwork is required, such as cable-stayed and arch bridges, or construction requirements such ...

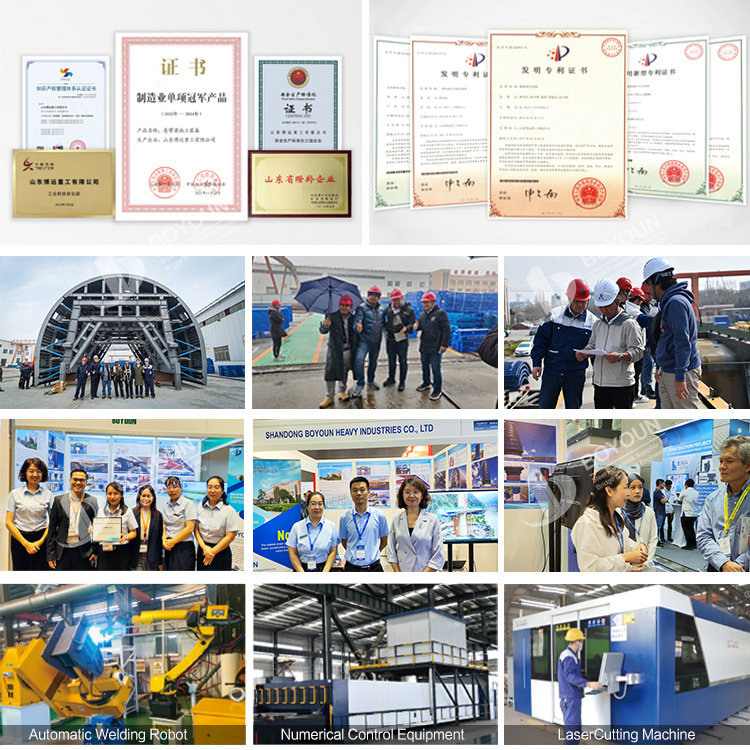

The form traveler formwork system is a non-standard mechanical equipment used for continuous cantilever construction. Advantages of Boyoun form traveler:Cantilever beam construction equipment champion; professional design team and after-sales team; leading industry standardization design since 2013, involved in formulating industry norms; delivering more than 1,000+ form traveler cases; the ...

The form traveller cantilever construction method is currently one of the most widely used methods for large-span pre-stressed concrete cantilever beams, continuous beams, and rigid frame bridges in the industry. ... After the concrete in the closure section reaches design strength, the remaining prestressing rods should be tensioned, and then ...

Product Description. Cantilever form traveler with main span below 150 meters refers to the form traveler applicable to bridges with main span below 150 meters. Scope of application:The cantilever form traveler with main span below 150 meters is suitable for the construction of small and medium-span bridges, including highway bridges, railroad ...

Project location: Yatai north street, Kuancheng district, Changchun, Ji'Lin Province Project year:2017 Form Traveler Design Principal on This Project: The bridge spans have many traffic lines, and according to the actual construction conditions, form traveller balanced cantilever construction method is the ideal choice.

Form traveller is the main equipment in cast-in-situ and balanced cantilever construction, has the advantages of simple structure, stress clear, easy disassembling anchoring forces and completely do not take up the road, etc. ... The bottom mould platform in the design of form traveller is composed of front and rear cross beam, bottom mould ...

Form Traveller. SDI FT is a cost - effective and reliable solution! Both the overhead and the underslung FT are designed for free cantilever construction of pre-stressed girder and cable - stayed concrete bridges. A standard underslung FT is designed for a segment length of 5 m. It can be tailor made for various segment lengths.

CNN —. On January 24, content creator Pelumi Nubi, who grew up in London, set off on a solo drive from the UK capital to Lagos, Nigeria in her beloved purple Peugeot 107. Over two months and a ...

April 15, 2024. This article is part of our Design special report previewing Milan Design Week. Designers are by definition manipulators — of materials, senses and expectations. There is nothing ...

Voting License Plate Contest! The winning design will be put on real license plates that all Arizona drivers can buy for their vehicles. A portion of the funds generated by the purchase of this license plate with the design may will go towards the Arizona National Guard. Thank you for participating in the License Plate Contest and making it a ...

Employee Travel and Reimbursement (ET&R) has included updates for the 2024 fiscal year-end process. Please use the information below as a reference for the fiscal year-end schedule related to out-of-pocket reimbursements, corporate card charges, and experimental subject payment forms. Out of Pocket Expenses* Both electronic and paper reimbursement forms must be submitted,

02:53 - Source: CNN. Beirut, Lebanon CNN —. A decades-long shadow war burst out into the open overnight as Iranian drones and missiles lit up the night sky in Israel and the occupied West Bank ...