Don't have an account? Subscribe

“Our goal is to help stakeholders understand the future of mobility.”

Home › News Releases › Ford Dagenham celebrates 90 years as London’s largest manufacturing location looks to the future

Ford Dagenham celebrates 90 years as London’s largest manufacturing location looks to the future

First Ford vehicle – a Ford AA truck – rolled off Dagenham’s production line on October 1, 1931

- By Automotive World

- October 8, 2021

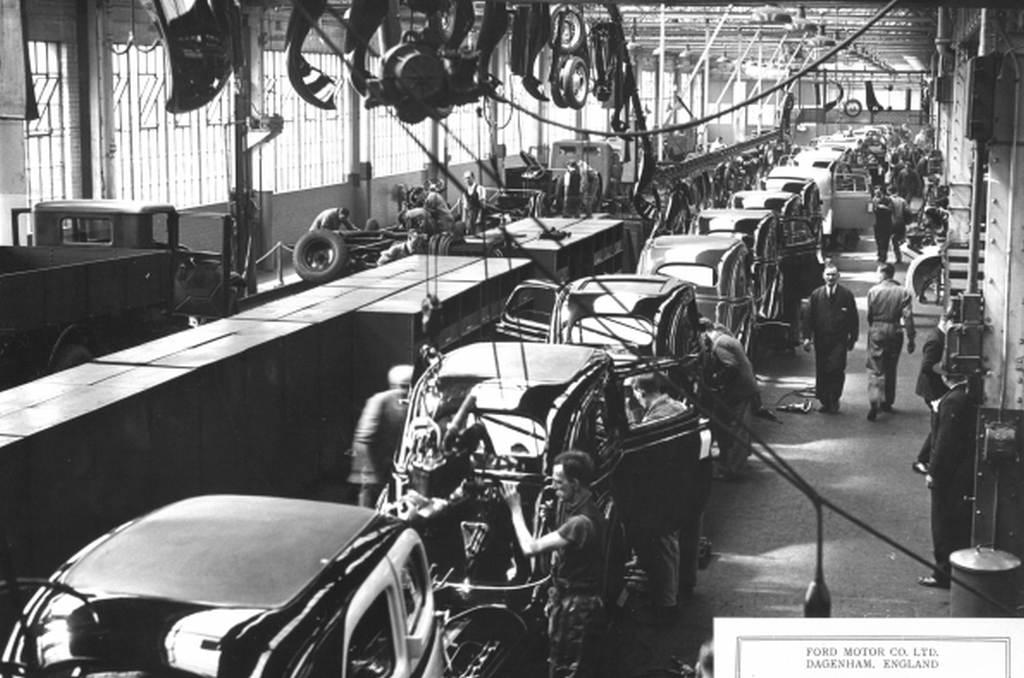

Just over 90 years ago, at 1:16pm on October 1, 1931, the first Ford vehicle rolled off the production line at what was then Ford’s newest global production facility, Ford Dagenham.

Nine decades later – with nearly 11 million cars, trucks and tractors built during 71 years of vehicle production which, if placed end to end, would stretch more than 400,000km or 10 times around the world, and close to 50 million engines produced to date – Dagenham continues to play a major role in Ford’s European operations, building the advanced technology diesel engines that power many of Ford’s passenger and commercial vehicles.

“Today is about celebrating with our employees the enormous contribution they and their predecessors have made over many generations to the success of Ford Dagenham,” said Kieran Cahill, chairman, Ford Motor Company Limited and vice president, Manufacturing Ford of Europe, speaking at a Ford employee event at Ford Dagenham today.

“Still London’s largest manufacturing site, the fact that Ford Dagenham continues to be such an important part of our European manufacturing operations is testament to our employees’ involvement in the site’s past, present and future.”

Ford Dagenham was confirmed in March of this year as the source of the latest advanced technology diesel engines for the next generation Ford Transit Custom range which will be built by Ford Otosan – Ford’s Turkish joint venture – in Kocaeli, Turkey, from early 2023 . The next generation Volkswagen 1-tonne commercial vehicle also will be built in Kocaeli as part of the Ford-Volkswagen Alliance.

“The anticipated incremental engine volumes this creates is expected to help safeguard jobs at Ford Dagenham. By 2025, we anticipate that up to 60 percent of our entire diesel engine volume will be destined just for the 1-tonne commercial vehicles being built by Ford Otosan,” said Martin Everitt, plant manager, Ford Dagenham.

Ford also announced earlier this year that Ford Dagenham will supply the diesel engine for a new light commercial vehicle to be manufactured at Ford’s Craiova facility in Romania from 2023.

In addition to diesel engine manufacturing, Ford Dagenham is also home to Ford’s Transport Operations which is responsible for the transport logistics of Ford components and vehicles across the U.K., and to a number of other functions, including Information Technology.

“Engines, Cars, Trucks, Tractors & Ventilators. What immediately comes to mind when I think of the 90 years anniversary, are the generations of families that have contributed to making this such a fantastic facility and helping us arrive at this milestone. All these people’s contributions over the years has been our true strength in Dagenham,” said Jason Brandon, Convenor, Dagenham Engine Plant.

“They have proven over and over again, both their versatility and their ability to rise to any challenge and when necessary diversify into other areas of manufacturing. We can do anything in Dagenham and I’m sure, notwithstanding the ongoing challenges for the internal combustion engine in the near future, we can secure future Ford opportunities in manufacturing and alternative sectors and give more generations of Ford families the opportunity to work for this great Company.“

“It is awesome to look back at how Dagenham has diversified over the years, making varied world leading products. All employees, past and present, should feel proud of what they have achieved. Looking to the future we have all the right ingredients for success, the most important ingredient being our employees who are motivated and dedicated to taking Dagenham forward into the world of electrified vehicles,” said Debbie Dempsey, Transport Operations Salaried Representative, Dagenham.

Dagenham – new opportunities and a gateway to the U.K. and beyond

From 1931 to 2002, Ford Dagenham built some of Ford’s most iconic European vehicles, from the Model Y to the Anglia, and the Zephyr to the Fiesta. Engine manufacturing also has been integral to Ford Dagenham since its earliest days, and while diesel engine production will remain the mainstay of Ford manufacturing operations at Dagenham in the years ahead, Ford also is looking at other opportunities across the Ford Dagenham site.

Announced in late June, the Ford Venari Alliance brings together Ford, the UK market leader in commercial vehicles and Venari, the UK’s largest emergency service vehicle provider, in plans to manufacture the all-new, lightweight front-line ambulance – unveiled by Ford and Venari earlier this year. Based on the Ford Transit chassis cab and developed under “Project Siren”, the lightweight ambulance was designed with input from industry experts and front-line medical teams.

The Ford Venari Ambulance is intended to be produced at a new facility in Ford Dagenham from 2022, utilising an existing, non-production location that will be refreshed to accommodate its manufacturing requirements. It is anticipated that the new business will create around 100 new jobs once production begins in 2022.

Ford and MS-RT, the Ford Pro commercial vehicles conversion partner and design-led automotive engineering company that creates specialised Ford vehicles that stand out on the road, also have announced that MS-RT is to establish a new £4 million vehicle conversion facility at Ford Dagenham.

The new Dagenham facility is intended to provide work for more than 50 new employees when it comes online in 2022, rising to over 120 new jobs when fully operational, helping in the regeneration of one of the UK’s most deprived areas, and is needed due to increasing customer demand for the company’s vehicle conversions both in the U.K. and in a number of European markets.

Thames Freeport – 1,700 acres of development land at the heart of Europe’s largest consumer market – c onnects Ford Dagenham to the ports at London Gateway and Tilbury. The Thames Freeport consortium partners, Ford, DP World London Gateway, and Port of Tilbury are working collaboratively with local authorities, and other public sector bodies such as the Thames Estuary Growth Board (TEGB), Port of London Authority (the PLA) and the South East LEP (SELEP), to catalyse investment opportunities along this strategic corridor, unleashing huge potential for local regeneration, sustainable and inclusive growth.

The Freeport has good onward road, rail and marine connections, alongside well-honed investment promotion, trade facilitation, skills development and automation services. It also is targeting green-tech growth, including future mobility solutions, supported by an Innovation Hub and local authorities committed to economic growth, and cements the Thames Estuary as the UK’s global gateway for trade

In 2020, Ford was part of the VentilatorChallengeUK consortium which manufactured much needed respiratory ventilators for the National Health Service. Ford transformed an empty warehouse into an ISO 9001-accredited ventilator sub-assembly manufacturing facility in just three weeks – a feat that would usually take a full year. This involved both the Dagenham and wider Ford team, in conjunction with the local community, coming together in challenging times to build, launch and staff the facility with up to five hundred people a day at peak production.

In addition to its role in building the most complex ventilator sub-assemblies, Ford also played the pivotal role in helping to industrialise the production process of the ventilators to enable them to be built in large scale – just as Henry Ford’s moving assembly line led to mass production in the car industry in 1908 with the Model T.

SOURCE: Ford

Advertisement

Join our linkedin group.

Let us help you understand the future of mobility

Related Content

April 12, 2024

Green light for series production: new Golf starts rolling off assembly line at Wolfsburg plant today

BMW Group is electrifying Plant Araquari

Ford highlights Freedom of Choice vehicle lineup in new campaign

Welcome back , to continue browsing the site, please click here

Title Sign up to our newsletter

Sign up now to get latest news, events, jobs and ticket giveaways from Barking and Dagenham Council

Sign up to our One Borough newsletter

Ford Dagenham Celebrates 90 years

Ford Dagenham recently celebrated its 90th anniversary, with the first cars having rolled off the production line in October 1931. Since then, Dagenham has helped keep Britain on the move, producing iconic models from the Model Y to the Anglia and the Zephyr to the Fiesta.

Now a centre of engine production, Ford is still an integral part of the borough’s identity and the nearly 11 million cars, trucks and tractors built over the years of vehicle production would stretch more than 400,000km or 10 times around the world – not forgetting the 50 million engines built.

And as the plant enters its tenth decade, the future looks bright too. In his recent Budget, the Chancellor announced that the Thames Freeport will begin operations from this month. In all, this exciting development will include over 21,000 new jobs with many more across supply chains alongside significant investment in training and skills, £4.5 billion in new public and private investment, and 1,700 acres of development land at the heart of Europe’s largest consumer market. Ford Dagenham is an important component of the Freeport area, which connects the facility to the ports at London Gateway and Tilbury.

Diesel engine production will remain integral to Ford operations at Dagenham in the years ahead, but Ford also is looking at other opportunities across the site. For example, the Ford Venari Ambulance is intended to be produced at a new facility in Ford Dagenham from 2022, making use of an existing non-production location that will be refreshed to accommodate the manufacturing requirements. It is anticipated that the new business will create around 100 new jobs once production begins in 2022.

Councillor Darren Rodwell, Leader, London Borough of Barking and Dagenham commented: “Ford is synonymous with Dagenham, and generations of local families have worked in the plant over its 90 years, many from the Becontree estate, which is celebrating its centenary this year. You could almost say the two have grown up together.

“Ford will also always be remembered for its role in the war effort, and for the women who led the Machinist’s Strike, which led to the historic Equal Pay Act.

“There’s also an exciting future ahead with the production of the Ford Venari Ambulance, as well as the Thames Freeport further anchoring Ford Dagenham as a vital part of the local economy.

“As we mark 90 years of Ford in Dagenham, I look forward to a successful ongoing relationship which best serves Barking and Dagenham and Ford’s place within it.”

- Press release

OneBorough Newsletter

Dagenham's famous Ford factory will become huge village with 3,500 homes

The old factory saw almost 11 million cars pass through its doors over 82 years

- 20:21, 14 MAR 2022

- Updated 20:26, 14 MAR 2022

Share your email to get the latest property news

We have more newsletters

Dagenham’s famous old Ford Factory is set to be turned into a huge new village after plans were approved on Monday by the local council. The new development will see over 3,500 new homes built with shops, offices and even a new school. The scheme’s developers said they hoped the plans would build a thriving new neighbourhood in East London.

Barking and Dagenham Council’s planning committee voted unanimously in favour of the plans to build the new village at a meeting on March 14. Some 3,502 new homes will be built on the empty site of what was once Dagenham’s Ford Factory. The factory was demolished following its closure in 2013.

The factory built almost 11 million cars between opening in 1931 before it finally closed down - an event was held in October to mark the 90th anniversary of the factory’s first car being built. The number of East Londoners employed at the factory reached a peak of around 40,000 in 1953, and 1,000 lost their jobs when the plant closed in 2013.

Now, the huge 45-acre site is set to become home to thousands of homes and thousands of square metres of offices and shops. The planning meeting heard that 47 per cent of the homes will be affordable for local residents. The newly-approved plans also include a secondary school for new and existing residents, new streets, parking spaces and a large park. Most of the new homes will be in small flat blocks between one and 19 storeys tall.

READ MORE: New tower block near East Croydon station with 118 flats is almost finished

Chair of the meeting councillor John Dulwich welcomed the plans, saying they were “an opportunity to utilise a key area in Dagenham.” Barking and Dagenham Council has previously approved 1,500 new homes in the area as part of a wider regeneration project.

Developers Peabody said they hoped the scheme would do much to improve the East London borough. Peabody representative James McMarland told the meeting: “This goes beyond a brick and mortar development - this is about building a community for residents.”

The developers also told the meeting they had worked with residents to add what they wanted to the plans, especially parks and public spaces. They added the scheme would bring “substantial benefits for Dagenham.” Brendan Sarfield, the company’s chief executive said when the plans were unveiled: “Like me, many people from the local community will have lived and breathed working at Ford Dagenham through their own experience or through family and friends.

“Together we have a fantastic opportunity to bring the empty site back into use as part of the exciting new Dagenham Docks neighbourhood. Starting with people, we can help bring the place to life, linking in with residents from the Becontree estate and elsewhere to make it a great Peabody neighbourhood for the future.”

No objections against the plans were put forward to the council at the meeting on January 14. The Greater London Authority (GLA) will now also consider the plans. Barking and Dagenham council officer James Coulstock said they may ask for 50 per cent affordable housing in the scheme.

- Barking and Dagenham

- Most Recent

Cookies on Zenoot

This website uses cookies to ensure you get the best experience on our website. More info

See Inside: The Ford engine factory in Dagenham

2019 marked 90 years since work started on constructing the Ford plant in Dagenham. We take a look inside and explore some of the facts & figures behind the site.

Picture: Ford of Britain

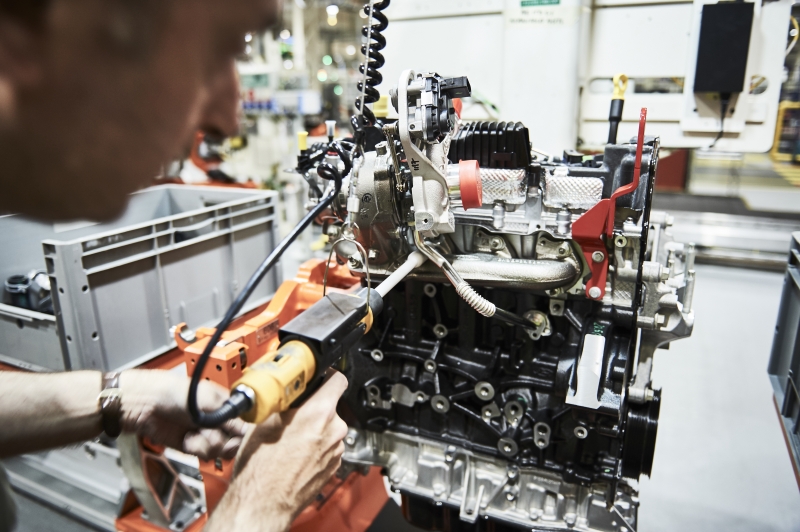

Ford built 11,000,000 cars in the UK before shifting its focus to engine production. Since 1984, more than 44,000,000 engines have been built by Ford in the UK.

It takes about an hour and a half for an engine to be manufactured and every 28 seconds, a finished unit reaches the end of the line.

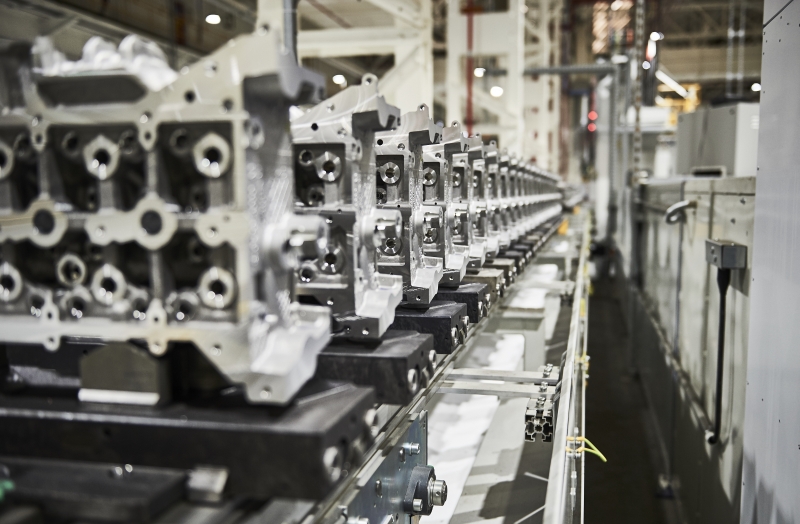

The ‘Panther line,’ produces the EcoBlue engines that go on to power vehicles including the Ford Transit, the best-selling commercial vehicle in Europe since its launch in 1965.

LED lighting is used throughout Dagenham, reducing energy consumption by 750,000kWh a year – enough to power 7500 houses for a week.

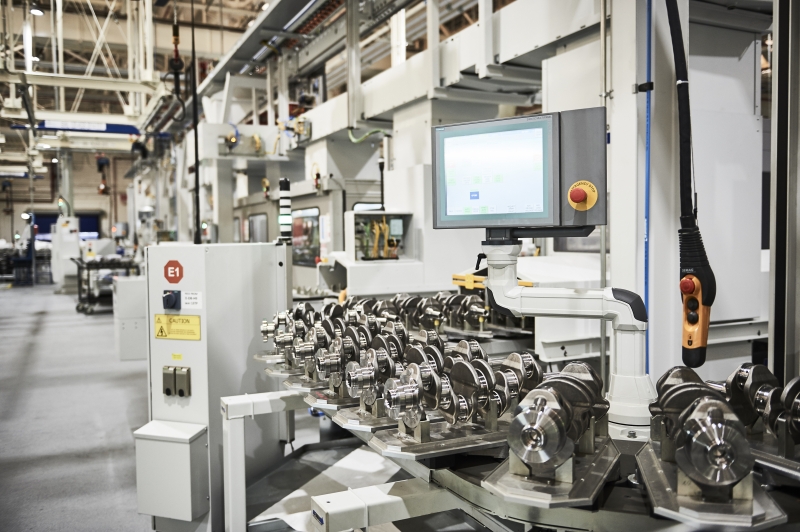

Crankshafts wait to be fitted to the EcoBlue engine. Each component is analysed both digitally and by human hand to ensure quality consistency.

The Dagenham plant has modernised at a rapid pace since it was founded in the 1930s. The lines are clean, efficient, safe and optimised for collaboration between the dextrous human hand and infallible digital systems.

The Ford Apprentice scheme has the widest range of roles on offer from any major manufacturer. Many managers at Dagenham started at Ford as apprentices, including current manufacturing manager, Chris Woolacott.

CEME is the Centre of Engineering and Manufacturing Excellence, and it is located on the Dagenham estate. It is a vocational university covering 25,000m2 and has education facilities for two thousand students. Most apprentices undertake an 18-month course at CEME before moving to their dealership, technological centre or plant to continue their training.

Drones in the factory? Well, yes – Ford employees are now using cameras mounted on drones to safely and efficiently inspect high-rise gantries, pipework and roof areas at the Dagenham Engine Plant. Maintenance staff can thoroughly inspect each area in just 12 minutes.

The Dagenham Diesel Centre was opened in 2003 by former Prime Minister Tony Blair. It still produces nearly 1,000,000 engines a year and is 100% wind powered, thanks to its three wind turbines – each turbine produces enough energy to power 1,000 homes.

Ford runs various projects that encourage more young people, particularly girls, to consider careers in STEM subjects. This includes supporting engineering challenges, such as Greenpower Trust, Formula Goblins and Formula24, to Primary Engineer and First Lego League events.

Ford directly supports the Primary Engineer programme, which aims to encourage primary-school-age children into engineering careers. This includes hosting events at its Technical Centre where students from local schools take part in a competition to showcase electric vehicle projects they had worked on for the previous eight months of the academic year.

Engines manufactured at Dagenham are exported around the world and shipped to Belgium, Germany, France, Italy, Turkey, Australia, Argentina and Japan.

Ford is one of the few manufacturers to have a positive gender pay gap – women earn on average 2% more than male colleagues. Ford Motor Company is one of only 230 companies across the world to be listed in Bloomberg’s 2019 Gender Equality Index, which recognises companies that demonstrate their commitment to female advancement and workplace equality.

The Panther engine plant at Dagenham is more than a mile long if you trace it from start to finish.

In 2018 Ford announced it had hit its global manufacturing CO2 emissions reduction target eight years early, a reduction of more than 3.4 million metric tons. Ford’s energy conservation programme played a major role in achieving the goal, including paint and other process improvements, LED lighting, plant consolidations and new energy-efficient facilities.

We would like to ‘See Inside’ your factory and share some insight about the investment, growth and future plans you have – if you wish to be featured, please get in touch on [email protected]

United States

Worldwide Locations

Select office or plant type.

Inside Ford’s secret retro and classic car collection

From cortinas to cosworths, we explore a ramshackle warehouse in dagenham stuffed with retro and classic fords.

Tucked away on the outskirts of Ford’s sprawling Dagenham factory is a small, slightly ramshackle warehouse.

Inside is a huge array of classic cars representing more than 110 years of Blue Oval history.

ALSO READ: Celebrating 50 years of classic Fords

From Cortinas to Cosworths, we lifted up the dust sheets to photograph the highlights.

Ford Sierra RS Cosworth

The mighty Sierra RS Cosworth celebrated its 30th birthday in 2016. A turbocharged 204hp 2.0-litre 16-valve engine meant 0-60mph in 6.2 seconds and a top speed of 149mph – serious stuff in 1986. This particular car was used for development work at Dunton, Essex, and is still fitted with a rollcage.

Ford Escort RS Cosworth

The 1992 Escort witnessed the second coming of Cosworth. It retained the trademark ‘whale tail’ wing of its predecessor (albeit as an option), but boasted 225hp and four-wheel drive. The ‘Cossie’ was also a successful rally car, before being replaced by the Focus WRC in 1999.

Ford Fiesta

The Fiesta is the UK’s most popular car. This 1976 model is 43 years old and – as a brief drive around Dagenham revealed – still in great shape. In fact, it was actually driven to Switzerland for a recent Geneva Motor Show. Not bad for 957cc…

The Mk2 Ford Fiesta arrived in 1983, facing rivals such as the Austin Metro and Vauxhall Nova. This is the back-to-basics 1.1 Popular Plus, with a four-speed manual gearbox.

Ford Fiesta XR2

The 1980s were the halcyon days of the hot hatch, and the Fiesta XR2 was one of the biggest sellers. With a bodykit, spotlights and ‘pepperpot’ alloys, it looked the business. Performance was less spectacular: 0-60mph in 10.2sec and 112mph flat-out.

Ford Model T

The 1908 Ford Model T was the first car to be mass-produced. Doing so brought costs down, putting cars within the reach of ‘normal’ people. Thus the Model T changed the world more, perhaps, than any other car. Unlike most old cars, it looks remarkably big alongside modern metal.

Now for something somewhat swifter… The RS200 is one of the fastest and most exclusive Fords ever made. A road-legal rally car, it had a mid-mounted 1.8-litre 250hp turbocharged engine and lightweight fibreglass body panels. Only 200 road cars were made.

The rallying version of the RS200 was even more extreme. Designed to compete in the notorious Group B, it was boosted to 450hp and could hit 62mph in 3.8 seconds. Sadly, the Group B era was cut short in 1986 after several fatal crashes.

Ford rally cars

Ford has a long history of rallying. Indeed, the rear-wheel-drive Mk1 and Mk2 Escorts and are among the most successful rally cars of all time. The Mk2 RS1800 in the foreground won the 1977 RAC Rally with Björn Waldegard at the wheel.

Ford Anglia 105E

Harry Potter fans will recognise this one. The Anglia 105E was built from 1959 to 1968 and had American-influenced styling, including small tailfins. Its 997cc engine accelerated the Anglia to 60mph in 26.9 seconds – probably not fast enough to take off…

Ford Escort Mexico

Now we’re talking. The Escort Mexico was a sporty special edition created to celebrate the Ford’s victory in the 1970 London to Mexico rally. This car was also displayed at the Geneva Motor Show, alongside the Sierra Cosworth featured earlier.

Ford Mondeo

A future classic? Certain members of the Motoring Research team certainly think so. This Mondeo GLX, complete with blue velour trim, would have been a sales rep’s dream back in 1994.

Ford Escort

Few people are likely to dream about a Mk5 Escort, but this example is notable for having covered just 800 miles from new. The much-maligned Escort was replaced by the Focus in 1998, a car that turned around Ford’s reputation.

Ford Escort XR3i

Here’s an Escort we can get excited about. The Mk4 XR3i wasn’t particularly special to drive, or even very quick (0-62mph in 9.1sec). But with its red go-faster stripes and racy graphics, it sums up the 1980s for us. Everyone loves a bit of nostalgia, right?

Another car very evocative of its era is the Capri. This 1977 example is one of the later Mk2 cars, and boasts a herculean 72hp from its 1.6-litre engine. Still, it could be worse: the 1.3-litre Capri produced just 55hp…

Ford Capri 280

With a 2.8-litre V6 under its lengthy bonnet, the 160hp Capri 280 had more than twice as much power as the lowly 1.6. This Brooklands Green beauty was the last hurrah before Ford discontinued the Capri for good – making it a highly sought-after special edition.

Ford Mustang

The Capri was effectively the European version of this car: the iconic Ford Mustang.

And here’s an example of the more recent Mustang – the full-fat 5.0-litre V8 version, no less. With 412 ponies to its name, the V8 ’Stang will hit 62mph in 4.8 seconds. Or you could just use the Line Lock function to create lots of tyre smoke. Better to burnout than fade away…

Ford Transits

Now for something altogether more practical. The Ford Transit van is approaching its 55th anniversary, and it remains the UK’s most popular commercial vehicle. The record for the highest number of people ever squeezed into a Transit is… 48.

Ford Transit

This is the oldest surviving roadworthy Ford Transit. It has a 64hp V4 engine, plus leaf-spring suspension front and rear. It would have cost £542 when new in 1965.

Ford Transit Connect X-Press

This one-off Transit is a little racier. Its running gear comes from a Mk1 Focus RS, which means 215hp – amplified by a Bosal sports exhaust. The X-Press also has lower suspension, a stiffer chassis and hip-hugging Recaro seats. We bet it’s a riot to drive.

Ford Transit Supervan 3

Ford built three Transit Supervans. This third version arrived in 1995, complete with a 650hp 3.5-litre engine from a Formula 1 car. It has since been fitted with a 2.9-litre Cosworth engine, which is being tinkered with here.

Ford Cortina

Here’s another one that takes us back. There was once a Mk5 Cortina on every suburban street in Britain, but they are all-but extinct now. This 1982 Cortina Crusader has a 91hp 1.6-litre petrol engine, Strato Silver paint and grey velour trim.

This is an earlier Mk3 Cortina from 1974. Its 1.3-litre Kent engine would have provided steady progress at best. However, we love the ‘Coke-bottle’ styling and very-70s lurid green paint.

Ford Granada

Above the Cortina sat Ford’s flagship: the spacious and luxurious Granada. Three body styles were available: four-door saloon, two-door coupe and the estate seen here. Few cars say ‘East End gangster’ like an old Granny…

The squarer Mk2 Granada was launched in 1977 and boasted innovations such as fuel injection and air conditioning. A prime candidate for a future Motoring Research Retro Road Test?

As if the Escort Cosworth wasn’t in-yer-face enough, how about one in bright yellow? The bloodline between the RS Cosworth variants of the Escort and Focus is clear to see.

Ford Focus RS500

Ford has a knack for producing ultra-desirable special editions, and the matte-black Mk2 Focus RS500 is just such a car. Its 2.5-litre turbocharged engine is cranked up to 350hp, giving 0-62mph in 5.4 seconds and a top speed of 165mph. Only 500 were made.

The meeting room

The meeting room at Ford’s Heritage Centre is just as fascinating as the cars. It looks like it hasn’t changed since about 1965. The bookshelves are crammed with dusty tomes about Ford history.

Model magic

There are some fantastic models on display, too. In the days before computer-aided design, scale models like the Mk1 Escort here were used to show managers and potential customers how a new car would look.

Some cars in the Ford Heritage collection get more love than others, and this 1996 Mk4 Fiesta clearly hasn’t moved for a while. Top marks for spotting the near-identical Mazda 121 version on the road.

Ford Fiesta XR2i

Another unloved Fiesta is the 1989 Mk3 XR2i. This lukewarm hatch gained fuel injection (hence the ‘i’ suffix) but lost the cheeky, fun-to-drive character of the Mk2 XR2. Not one of the finest fast Fords.

Few things say ‘1970s’ like a beige Mk1 Fiesta with brown vinyl upholstery. Although this lovely example actually dates from 1981.

Formula Ford

Tucked away behind the fibreglass front of the Supervan 3 (it’s having work done, remember?) is a Formula Ford racing car. The series has served as a springboard for many Formula 1 drivers since the 1960s.

Rolling chassis

The Ford Heritage Centre isn’t a museum, and many of the cars are works-in-progress. Three guesses as to what this rolling chassis belongs to. We know it’s a Ford, but beyond that we’re stumped…

Ford Model A

As the car that replaced the Model T, the 1927 Model A had a tough act to follow. UK versions had a 2.0-litre 28hp engine and were available in a huge range of body styles – from roadster to panel van. Note the rear-hinged ‘suicide’ doors.

Ford Model Y

The Model A gave way to the Model Y in 1931. A compact car well suited to European roads, the Y had a 933cc engine and a top speed of 60mph. It remained in production until 1937.

Ford Zodiac

With its two-tone paint and plentiful chrome, the Mk2 Ford Zodiac was clearly influenced by more glamorous cars from across the pond. The Zodiac was the upmarket version of the contemporary Ford Zephyr.

Finished in what looks like period ‘British Telecom yellow’, this Transit will look oddly familiar to anyone who remembers the 1980s. Spot the promotional World Rally Transit from 2001 in the background.

Ford Thames 307E

The Ford Thames was essentially a commercial version of the Anglia. In fact, it was renamed the Anglia van after 1965. The chrome grille marks this out as being the more capable 7cwt version of the 307E – others had a basic, painted metal grille.

Ford Quadricycle

This Ford Quadricycle is actually a replica, made by apprentices in July 1963 for the Henry Ford centenary. It’s a faithful reproduction of the first vehicle Ford built in 1896.

We couldn’t resist another XR2. We borrowed this car for one of our Retro Road Tests – and didn’t want to give it back. It’s crude and almost comically basic by modern standards, but fabulous fun. And it got a hero’s welcome on the streets of Dagenham.

Ford Fiesta ST

Can’t afford the brilliant new Fiesta ST? Don’t worry, neither can we. The Mk5 ST, however, is a cheaper alternative that is ageing well. Prices are starting to rise, so grab one while you can.

More models

How cool is this Mk4 Zodiac model? The real thing was powered by a 3.0-litre V6, and a very stylish way to travel in 1966.

Number crunchers

Before microchips, mechanical adding machines were used to calculate Ford’s profit and loss. These perfectly-preserved examples are in the Heritage Centre meeting room.

The Mk2 Cortina was launched in 1966, and in 1967 it became Britain’s best selling car. This dusty 1600 Super still looks great.

We even love the Cortina’s chrome badges. From an era before ‘metal-effect’ plastic…

As our gallery draws to a close, let’s go back to the beginning with the Ford Model T. Looks like this Tin Lizzy has a slight oil leak…

A treasure trove of Ford history

Sadly, the Ford Heritage Collection isn’t open to the public, but we hope you enjoyed this peek beneath the dust sheets.

- Related Topics

- Classic Cars

Related Articles

Last lap: Lamborghini Huracan bows out with STJ special edition

Revealed: Morgan updates Plus Four sports car for 2024

Hot Audi S3 upgraded with more power and greater agility

20 COMMENTS

Find a car review.

Best luxury cars to buy in 2024

BMW reveals details of new M5 Touring – due later this year

Chasing 007: On the trail of James Bond in Scotland

RML Short Wheelbase: the story behind Britain’s retro supercar

McLaren Artura: tech secrets of new hybrid supercar revealed

Best luxury SUVs to buy in 2024

Best family SUVs to buy in 2024

Zebra, Pelican or Tiger? Every type of pedestrian crossing explained

What do all your car’s dashboard warning lights mean?

13 easy ways to save money on fuel

Why Register?

You will be able to access:

Content tailored to your personal preferences, Favorite content saved within your briefcase, Media advisories, newsletters, and email alerts and PR contact information

Forgot Password

Enter your email below and we'll send a link to help you access your account.

Sorry, your email address is not recognized.

An email has been sent.

Instructions on how to reset your password have been sent to the email you entered.

FORD MEDIA CENTER

Great Britain | English Select a location

Ford Media Center

Remade in Dagenham: new homes and green spaces on the way for historic factory site

- March 14, 2024

Ford’s iconic stamping plant factory in Dagenham, East London, which gained fame through the historic equal pay strikes depicted in the film “Made in Dagenham,” is undergoing a remarkable transformation.

The 45-acre site, once a key part of the powerhouse of East End industry where nearly 11 million Ford cars were manufactured, will soon be home to a dynamic new neighbourhood with thousands of much-needed homes and amenities, including a new urban park.

Ford’s stamping plant, which closed in 2013, was the site of the pivotal 1968 strike led by female sewing machinists, who were advocating for equal pay for comparable work. Their courageous stand ultimately paved the way for the Equal Pay Act in 1970.

Dagenham, with a heritage dating back 4,000 years, has witnessed a remarkable transformation from a historic barrier along the Thames to the site of Europe’s largest car plant. Notable for its history as a hub of industry and commerce, it once hosted a timber dock and shipping company.

In 2021, the Mayor of London provided a £80m grant from the Mayor’s Affordable Housing Programme to enable Peabody to acquire the site. The Hill Group then entered a joint venture with

Peabody to deliver the development of the first phase, with construction getting underway in March 2023. The shared vision is to redefine the landscape of East London once again and bring new life to the area over the next decade.

Spanning multiple phases, the ambitious project aims to deliver more than 3,500 homes, with 1,640 set to be affordable for local residents. Once complete, Dagenham Green will also boast 10 acres of expansive parks and play spaces.

Phase one, which constitutes just over a quarter of the total homes, will see the construction of 935 homes, 35 percent of which will be affordable. Situated in the south-west corner of the site, adjacent to Dagenham Dock railway station, it will serve as the gateway to the broader masterplan area, which received outline planning approval in March 2022 following extensive consultation with the community.

Drawing inspiration from the marshland, a key feature of phase one will be the first section of a new five-acre urban park complete with a large pond, children’s play areas, and a heritage trail commemorating the legacy of the Dagenham women who championed equal pay rights in the 1960s.

There will also be a market square linking Dagenham Green to the nearby railway station, fostering connectivity and a strong sense of community. Phase one will also incorporate more than 1,600 square metres of non-residential space, for commercial, social, and leisure activities. The first residents are expected to move in from the summer of 2025.

The project also prioritises sustainability, with plans for biodiverse green spaces and an air-source heat pump energy centre for the production of low-carbon energy.

During construction, the partners are committed to providing 48 apprenticeship opportunities and employing 25 percent of the workforce from the local area, with extensive training programmes offered to participants.

Peabody and its partners, including Hill, the Greater London Authority (GLA), Barking and Dagenham Council, and Be First Regeneration Ltd came together on Thursday 22 February to see how the redevelopment is progressing.

Philip Jenkins, Executive Director of Development at Peabody, said: “At a time when all development is challenging, it’s always exciting to see tower cranes at work and construction progressing so rapidly. With thousands of much-needed new homes and facilities on their way for Dagenham, the development promises to be a landmark project, blending modern amenities with features that celebrate the area’s rich heritage. From its industrial heyday to becoming a symbol of progress in the fight for equal pay, Dagenham Green will create a vibrant new neighbourhood, and we look forward to welcoming new residents from 2025.”

Andy Fancy, Managing Director at The Hill Group , said: “It is truly inspiring to gather here alongside Peabody, esteemed council members, and representatives from the GLA, to celebrate the remarkable strides achieved here in Dagenham. The realisation of a project of this magnitude takes years of meticulous planning and collaboration with partners and stakeholders. This collective effort is instrumental in the continual growth and success of this exciting new community.”

Cllr Darren Rodwell, Leader of the Council, said: “We’re proud of our history in Barking and Dagenham and I’m pleased that this nationally important site, where women fought for equal rights in 1968 and 1984, will once again play a key part in our community – providing new, safe homes for residents.

“I’m glad to be working with Peabody on this project and I think it’s fantastic that they’re not just focusing on homes but also on creating green spaces and a market for the community to come together and enjoy.

“And not only that, with a large proportion of the workforce coming from B&D and dozens of apprenticeships being created for local people this project will be a huge boost to the borough as a whole.”

The Deputy Mayor of London for Housing and Residential Development, Tom Copley, said: “I’m delighted that Dagenham’s famous Ford factory is being revamped to deliver over 3,500 high-quality new homes, with nearly half of these set to be genuinely affordable for local residents. “This promises to be a truly impressive development utilising the very best in modern architecture and design, whilst maintaining the unique heritage and character of the local area. The green spaces and parks, fantastic new amenities and community spaces, job and apprenticeship opportunities, and excellent transport links on offer will have huge benefits for the local community – helping to build a fairer, greener, more prosperous London for all.”

Building, Design & Construction Magazine | The Choice of Industry Professionals

BDC News Team

Latest issue.

BDC 315 : Apr 2024

Support 110 years of independent journalism.

- Environment

(Not) Made in Dagenham: Why electric vehicles aren’t rolling out of Ford’s iconic factory

UK-based car companies are struggling with the electric revolution.

By Nick Ferris

For decades, one car ruled British roads: the Ford Fiesta. The compact five-seater provided a cheap and reliable transport option to millions of families, selling more than any other model since its launch in the UK in 1977. For most of that time, nearly all UK Fiestas came from one location: the Ford factory in Dagenham, East London.

When the factory opened in 1931, cars were large, ornate machines, beyond most people’s budgets. But Ford Dagenham was one reason why that changed: it was the largest car plant in Europe, producing tens of thousands of vehicles a year by the end of the decade and employing 40,000 workers by 1943. Over seven decades, iconic models including the Cortina, Capri and Sierra were all made at Dagenham. The site even became a milestone in the UK women’s liberation movement, when in 1968 Ford sewing machinists went on strike to fight for pay parity with their male colleagues – popularised in the 2010 film Made in Dagenham .

By the time the last Ford Fiesta rolled off the production line in 2002, the plant had produced 11 million vehicles. However, it was no longer competitive with modern facilities in Germany and Spain. Ford transformed the factory to become its global centre for the production of diesel engines. The site remains London’s largest factory, and has produced some 50 million engines to date.

Now though, there is a new threat to Ford Dagenham. The company, like every other major car brand, has committed to decarbonise its production line to meet government plans to outlaw internal combustion engines for cars and vans — the UK is aiming for 2030, EU countries by 2035. The pledge could spell the end of Ford Dagenham, unless a new facility is developed to build electric cars.

“Dagenham will keep producing diesel engines for Ford as long as there is demand around the world,” says Des Quinn from the Unite Union, which represents Ford Dagenham workers. “But the concern is that this demand is only going to keep falling. And we don’t want Dagenham to wither and die on the vine”.

In the short-term, Ford plans to concentrate more on fossil fuel engine production at the Dagenham site. But this economic opportunity could prove to be a poisoned chalice longer-term, if the site misses out on electric investment. Unite is in conversation with Ford about new opportunities, but it is hard to find a solution that will keep all 2,275 workers employed. “One option could be a new battery plant”, says Quinn. “But this is unlikely, as these tend to go near car production plants, which Ford no longer has in this country.”

[See also: What Fordâ?Ts new headquarters tells us about the future of transport ]

In March, Ford announced the launch of seven new electric car models in Europe by 2024 and $2bn worth of investment for these to be developed at its production site in Cologne in Germany. No new investment was announced for Dagenham, which has now not produced Ford cars for 20 years.

Manufacturers everywhere are under immense commercial pressure as they grapple with a global shortage of semiconductors, supply chain disruptions because of Covid and the war in Ukraine, and uncertain economic headwinds. The challenge of net zero is also profound. A recent study from the NGO Influence Map found that only two of the world’s 12 top automakers - Tesla and Mercedes-Benz - are planning to make enough electric vehicles by 2030 to keep in step with Paris Agreement climate goals.

There are also commercial difficulties specific to the UK. “The uncertainty of Brexit hanging over the industry between the 2016 referendum and the 2020 deal going through on Christmas Eve made the UK a really hard place to invest in,” says Mike Hawes, the CEO of the Society of Motor Manufacturers and Traders (SMMT), which represents UK auto manufacturers. UK car production has halved since 2016. Having once been the world's second biggest car manufacturer, it has now fallen out of the top 15.

The government has taken some steps to encourage companies like Ford to stay in the UK. In 2013, for example, it set up the Advanced Propulsion Centre to facilitate UK-based research and development into low-carbon technologies. Ford has collaborated with the centre on seven research projects and received funding to transform a second smaller plant in Merseyside into an electric car parts factory by 2024. But no such deal was been announced for Dagenham.

Other UK car manufacturers have committed to electrify UK production, including Toyota, whose Burnaston plant produces nearly 90 per cent hybrid vehicles, and Nissan, which is developing a £1bn electric car hub at its Sunderland plant. Jaguar Land Rover (JLR), the UK’s largest manufacturer by volume, is set to only produce electric Jaguars by 2025, with Land Rovers following suit by 2035. However, recent reports suggest that Coventry-based JLR may build a range of new EVs in Slovakia because of a lack of battery manufacturing capacity in the UK.

For now, Ford is betting on a slow transition to electric vans — a spokesman for the company said he believes “the majority" of van sales will still be diesel at the turn of the decade. But sheer belief will not be enough to stymie the transition if countries are serious about meeting ambitious emissions reduction pledges, and the price of new technologies continues to fall. Electric vans are already cheaper to run than their diesel counterparts on a lifetime basis.

Dagenham has got "its own jetty on the River Thames, which makes it great for exports; a great industrial relations record; it’s a nice place in the world to live; and it’s got a history that Ford is rightly proud of, ” says Unite's Quinn. But these attributes alone won't be enough to secure the factory's future in a carbon-constrained world.

[See also: Why the godfather of the electric car is betting on public transport]

The Saturday Read

Morning call, events and offers, the green transition.

- Administration / Office

- Arts and Culture

- Board Member

- Business / Corporate Services

- Client / Customer Services

- Communications

- Construction, Works, Engineering

- Education, Curriculum and Teaching

- Environment, Conservation and NRM

- Facility / Grounds Management and Maintenance

- Finance Management

- Health - Medical and Nursing Management

- HR, Training and Organisational Development

- Information and Communications Technology

- Information Services, Statistics, Records, Archives

- Infrastructure Management - Transport, Utilities

- Legal Officers and Practitioners

- Librarians and Library Management

- OH&S, Risk Management

- Operations Management

- Planning, Policy, Strategy

- Printing, Design, Publishing, Web

- Projects, Programs and Advisors

- Property, Assets and Fleet Management

- Public Relations and Media

- Purchasing and Procurement

- Quality Management

- Science and Technical Research and Development

- Security and Law Enforcement

- Service Delivery

- Sport and Recreation

- Travel, Accommodation, Tourism

- Wellbeing, Community / Social Services

Content from our partners

Unlocking the potential of a national asset, St Pancras International

Time for Labour to turn the tide on children’s health

How can we deliver better rail journeys for customers?

Harold Wilson’s lessons for Labour

The housing market was supposed to crash, so did it or didn’t it?

Who killed Thames Water?

- OH&S, Risk Management

- Skip to primary navigation

- Skip to main content

Our Thinking

Ford dagenham factory tour.

Please note this article was published before OEE Consulting and gobeyond joined forces to become Gobeyond Partners .

On April 28th OEE Consulting hosted the latest Service Excellence Network event at the CEME Conference Centre in Dagenham.

The morning was arranged as two parallel sessions with one group visiting the Ford Dagenham Engine Factory and the other hearing from guest speaker Mark Galvin, Critical Concern Manager for Ford. Mark has been responsible for rolling out a new approach to quality which put the ‘voice of customer’ at the heart of their operating model and radically improved customer satisfaction. Feedback from the session was how useful it was to hear from an organisation where voice of the customer was so well embedded within the operation.

The second group were treated to a tour of two production lines at the Engine Plant, and were able to see the scale and pace of a modern, lean manufacturing facility. Members saw the common ground between service and manufacturing when discussing team boards, engagement among the workforce and the importance of standardisation. They were fascinated by the blend of automation and manual operations, and the relentless focus on productivity and continuous improvement created by their expertly designed operating model . Precision that leads to an engine being produced every 25 seconds. The high standard of visual management was a key theme, with members commenting on the strength & clarity of the visual tools being used by the operation.

The second part of the morning was a presentation from Nigel Lombard, Managing Director and Founder of Drivology a new type of insurance provider. Nigel spoke passionately about his experiences starting up a business using disruptive technology in the very traditional car insurance industry. He told the story from the early idea stage to getting the business up-and-running to now renewing the first policies. Nigel spoke very honestly about his experience setting up Drivology commenting on the sleepless nights that go hand in hand with starting your own business.

After lunch Mark Bilney Head of Learning and Development for OEE and guest speaker Heather Townsend author of award-winning book “The FT Guide to Business Networking” gave a joint presentation/interactive networking session. The group was given insight into how using their network is crucial to influence key stake holders within their business, and how people respond to information differently making it key to adapt our behaviour to relevant situations. Both presenters told memorable stories as well as using engaging interactive exercises to illustrate their points and explain their operating model.

Thank you to all our guest speakers and the members that were able to attend. The day was a great networking opportunity as well as delivering quality talks from a variety of experienced speakers.

Richard Chataway looks at some of the ways in which behavioral science can begin to prepare us for this brave new world.

Gobeyond Partners has received the Highly Commended Award in the "People and Leadership" category in collaboration with First Bus at this year's Management Consultancies Association (MCA) Awards.

We’re delighted to announce Rich Mansell has joined Gobeyond Partners, in the role of Consulting Director to support its rapidly growing Banking, Financial Services and Insurance (BFSI) sector.

Stay informed. Never miss our email updates.

The future of service forum.

The Future of Service Forum brings together like-minded organisations from across the service sector. Each is committed to improving operations, creating networking opportunities and providing access to insight and content contributors.

Looking for the best Aussie casino experience? Joe Fortune Australia offers unparalleled entertainment!

Where winners play at Mr Bet ! Place your bets and claim victory.

Dive into a world of fun at Liberty Slots ! Experience top slots with exclusive bonuses today!

Unleash excitement at Pokie Pop ! Discover vibrant games and win big! Your adventure begins here!

Explore the best Australian slots at The Pokies ! Your jackpot journey starts now!

Enter the thrilling world of Dazard for an unparalleled gaming experience! Your luck awaits!

- Français ( French )

- Deutsch ( German )

- 简体中文 ( Chinese (Simplified) )

- 繁體中文 ( Chinese (Traditional) )

Ford Dagenham plant celebrates 90th anniversary

10 Minute Read

Just over 90 years ago, at 1:16pm on October 1, 1931, the first Ford vehicle rolled off the production line at what was then Ford’s newest global production facility, Ford Dagenham.

Nine decades later – with nearly 11 million cars, trucks and tractors built during 71 years of vehicle production which, if placed end to end, would stretch more than 400,000km or 10 times around the world, and close to 50 million engines produced to date – Dagenham continues to play a major role in Ford’s European operations, building the advanced technology diesel engines that power many of Ford’s passenger and commercial vehicles.

“Today is about celebrating with our employees the enormous contribution they and their predecessors have made over many generations to the success of Ford Dagenham,” said Kieran Cahill, chairman, Ford Motor Company Limited and vice president, Manufacturing Ford of Europe, speaking at a Ford employee event at Ford Dagenham today.

“Still London’s largest manufacturing site, the fact that Ford Dagenham continues to be such an important part of our European manufacturing operations is testament to our employees’ involvement in the site’s past, present and future.”

Ford Dagenham was confirmed in March of this year as the source of the latest advanced technology diesel engines for the next generation Ford Transit Custom range which will be built by Ford Otosan – Ford’s Turkish joint venture – in Kocaeli, Turkey, from early 2023. The next generation Volkswagen 1-tonne commercial vehicle also will be built in Kocaeli as part of the Ford-Volkswagen Alliance.

“The anticipated incremental engine volumes this creates is expected to help safeguard jobs at Ford Dagenham. By 2025, we anticipate that up to 60 percent of our entire diesel engine volume will be destined just for the 1-tonne commercial vehicles being built by Ford Otosan,” said Martin Everitt, plant manager, Ford Dagenham.

Ford also announced earlier this year that Ford Dagenham will supply the diesel engine for a new light commercial vehicle to be manufactured at Ford’s Craiova facility in Romania from 2023.

In addition to diesel engine manufacturing, Ford Dagenham is also home to Ford’s Transport Operations which is responsible for the transport logistics of Ford components and vehicles across the U.K., and to a number of other functions, including Information Technology.

“Engines, Cars, Trucks, Tractors & Ventilators. What immediately comes to mind when I think of the 90 years anniversary, are the generations of families that have contributed to making this such a fantastic facility and helping us arrive at this milestone. All these people’s contributions over the years has been our true strength in Dagenham,” said Jason Brandon, Convenor, Dagenham Engine Plant.

“They have proven over and over again, both their versatility and their ability to rise to any challenge and when necessary diversify into other areas of manufacturing. We can do anything in Dagenham and I’m sure, notwithstanding the ongoing challenges for the internal combustion engine in the near future, we can secure future Ford opportunities in manufacturing and alternative sectors and give more generations of Ford families the opportunity to work for this great Company.“

“It is awesome to look back at how Dagenham has diversified over the years, making varied world leading products. All employees, past and present, should feel proud of what they have achieved. Looking to the future we have all the right ingredients for success, the most important ingredient being our employees who are motivated and dedicated to taking Dagenham forward into the world of electrified vehicles,” said Debbie Dempsey, Transport Operations Salaried Representative, Dagenham.

Dagenham – new opportunities and a gateway to the UK and beyond

From 1931 to 2002, Ford Dagenham built some of Ford’s most iconic European vehicles, from the Model Y to the Anglia, and the Zephyr to the Fiesta. Engine manufacturing also has been integral to Ford Dagenham since its earliest days, and while diesel engine production will remain the mainstay of Ford manufacturing operations at Dagenham in the years ahead, Ford also is looking at other opportunities across the Ford Dagenham site.

Announced in late June, the Ford Venari Alliance brings together Ford, the UK market leader in commercial vehicles and Venari, the UK’s largest emergency service vehicle provider, in plans to manufacture the all-new, lightweight front-line ambulance – unveiled by Ford and Venari earlier this year. Based on the Ford Transit chassis cab and developed under “Project Siren”, the lightweight ambulance was designed with input from industry experts and front-line medical teams.

The Ford Venari Ambulance is intended to be produced at a new facility in Ford Dagenham from 2022, utilising an existing, non-production location that will be refreshed to accommodate its manufacturing requirements. It is anticipated that the new business will create around 100 new jobs once production begins in 2022.

Ford and MS-RT, the Ford Pro commercial vehicles conversion partner and design-led automotive engineering company that creates specialised Ford vehicles that stand out on the road, also have announced that MS-RT is to establish a new £4 million vehicle conversion facility at Ford Dagenham.

The new Dagenham facility is intended to provide work for more than 50 new employees when it comes online in 2022, rising to over 120 new jobs when fully operational, helping in the regeneration of one of the UK’s most deprived areas, and is needed due to increasing customer demand for the company’s vehicle conversions both in the U.K. and in a number of European markets.

Thames Freeport – 1,700 acres of development land at the heart of Europe’s largest consumer market – connects Ford Dagenham to the ports at London Gateway and Tilbury. The Thames Freeport consortium partners, Ford, DP World London Gateway, and Port of Tilbury are working collaboratively with local authorities, and other public sector bodies such as the Thames Estuary Growth Board (TEGB), Port of London Authority (the PLA) and the South East LEP (SELEP), to catalyse investment opportunities along this strategic corridor, unleashing huge potential for local regeneration, sustainable and inclusive growth.

The Freeport has good onward road, rail and marine connections, alongside well-honed investment promotion, trade facilitation, skills development and automation services. It also is targeting green-tech growth, including future mobility solutions, supported by an Innovation Hub and local authorities committed to economic growth, and cements the Thames Estuary as the UK’s global gateway for trade

In 2020, Ford was part of the VentilatorChallengeUK consortium which manufactured much needed respiratory ventilators for the National Health Service. Ford transformed an empty warehouse into an ISO 9001-accredited ventilator sub-assembly manufacturing facility in just three weeks – a feat that would usually take a full year. This involved both the Dagenham and wider Ford team, in conjunction with the local community, coming together in challenging times to build, launch and staff the facility with up to five hundred people a day at peak production.

In addition to its role in building the most complex ventilator sub-assemblies, Ford also played the pivotal role in helping to industrialise the production process of the ventilators to enable them to be built in large scale – just as Henry Ford’s moving assembly line led to mass production in the car industry in 1908 with the Model T.

About Ford Motor Company

Ford Motor Company is a global company based in Dearborn, Michigan. The company designs, manufactures, markets and services a full line of Ford cars, trucks, SUVs, electrified vehicles and Lincoln luxury vehicles, provides financial services through Ford Motor Credit Company and is pursuing leadership positions in electrification; mobility solutions, including self-driving services; and connected services. Ford employs approximately 187,000 people worldwide. For more information regarding Ford, its products and Ford Motor Credit Company, please visit www.corporate.ford.com.

Ford of Britain has been sales leader in the U.K. for passenger vehicles and commercial vehicles for 44 and 55 consecutive years respectively, with Fiesta being the country’s top-selling vehicle the last 12 years. The U.K. is Ford’s third-largest global market, accounting for around 30 percent of Ford total vehicle sales in Europe. Ford is going “all-in” on electrification, with its passenger vehicle range moving to all-electric by 2030. Ford directly employs around 7,000 people in the U.K., with thousands more employed in its extensive dealer network. The Ford Britain Dunton Campus in Essex is the home of Ford’s European commercial vehicle business group, the Ford of Britain national sales company, Ford’s banking arm – Ford Credit Europe – and powertrain engineering. Around 85 percent of engines and all transmissions built in the U.K. are exported to more than 15 countries on six continents. Total value of Ford exports is around £2.5 billion annually.

More from MTDMFG

Visit the MTDMFG Profile

View Vacancies

MTDMFG showcases the news and videos from the UK's thriving manufacturing sector, that you probably won't find in the mainstream media.

Thank you, we will be in contact shortly.

Cookie Usage

Our website uses cookies to enhance your experience. Using this website you agree to the use of cookies.

Are you enjoying this article?

Sign up to our email newsletter and don't miss out on more articles like this.

Do you give consent for MTDMFG to send you communications?

You can unsubscribe at any time by clicking the link in the footer of our emails.

Ford Dagenham celebrates 90 years as London’s largest manufacturing location

Article continues below:

Nine decades later – with nearly 11 million cars, trucks and tractors built during 71 years of vehicle production which, if placed end to end, would stretch more than 400,000km or 10 times around the world, and close to 50 million engines produced to date – Dagenham continues to play a major role in Ford’s European operations, building the advanced technology diesel engines that power many of Ford’s passenger and commercial vehicles.

“Today is about celebrating with our employees the enormous contribution they and their predecessors have made over many generations to the success of Ford Dagenham,” said Kieran Cahill, chairman, Ford Motor Company Limited and vice president, Manufacturing Ford of Europe, speaking at a Ford employee event at Ford Dagenham today.

“Still London’s largest manufacturing site, the fact that Ford Dagenham continues to be such an important part of our European manufacturing operations is testament to our employees’ involvement in the site’s past, present and future.”

Ford Dagenham was confirmed in March of this year as the source of the latest advanced technology diesel engines for the next generation Ford Transit Custom range which will be built by Ford Otosan – Ford’s Turkish joint venture – in Kocaeli, Turkey, from early 2023. The next generation Volkswagen 1-tonne commercial vehicle also will be built in Kocaeli as part of the Ford-Volkswagen Alliance.

“The anticipated incremental engine volumes this creates is expected to help safeguard jobs at Ford Dagenham. By 2025, we anticipate that up to 60 percent of our entire diesel engine volume will be destined just for the 1-tonne commercial vehicles being built by Ford Otosan,” said Martin Everitt, plant manager, Ford Dagenham.

Ford also announced earlier this year that Ford Dagenham will supply the diesel engine for a new light commercial vehicle to be manufactured at Ford’s Craiova facility in Romania from 2023.

In addition to diesel engine manufacturing, Ford Dagenham is also home to Ford’s Transport Operations which is responsible for the transport logistics of Ford components and vehicles across the U.K., and to a number of other functions, including Information Technology.

“Engines, Cars, Trucks, Tractors & Ventilators. What immediately comes to mind when I think of the 90 years anniversary, are the generations of families that have contributed to making this such a fantastic facility and helping us arrive at this milestone. All these people’s contributions over the years has been our true strength in Dagenham,” said Jason Brandon, Convenor, Dagenham Engine Plant.

“They have proven over and over again, both their versatility and their ability to rise to any challenge and when necessary diversify into other areas of manufacturing. We can do anything in Dagenham and I’m sure, notwithstanding the ongoing challenges for the internal combustion engine in the near future, we can secure future Ford opportunities in manufacturing and alternative sectors and give more generations of Ford families the opportunity to work for this great Company.“

“It is awesome to look back at how Dagenham has diversified over the years, making varied world leading products. All employees, past and present, should feel proud of what they have achieved. Looking to the future we have all the right ingredients for success, the most important ingredient being our employees who are motivated and dedicated to taking Dagenham forward into the world of electrified vehicles,” said Debbie Dempsey, Transport Operations Salaried Representative, Dagenham.

Dagenham – new opportunities and a gateway to the U.K. and beyond From 1931 to 2002, Ford Dagenham built some of Ford’s most iconic European vehicles, from the Model Y to the Anglia, and the Zephyr to the Fiesta. Engine manufacturing also has been integral to Ford Dagenham since its earliest days, and while diesel engine production will remain the mainstay of Ford manufacturing operations at Dagenham in the years ahead, Ford also is looking at other opportunities across the Ford Dagenham site.

Announced in late June, the Ford Venari Alliance brings together Ford, the UK market leader in commercial vehicles and Venari, the UK’s largest emergency service vehicle provider, in plans to manufacture the all-new, lightweight front-line ambulance – unveiled by Ford and Venari earlier this year. Based on the Ford Transit chassis cab and developed under “Project Siren”, the lightweight ambulance was designed with input from industry experts and front-line medical teams.

The Ford Venari Ambulance is intended to be produced at a new facility in Ford Dagenham from 2022, utilising an existing, non-production location that will be refreshed to accommodate its manufacturing requirements. It is anticipated that the new business will create around 100 new jobs once production begins in 2022.

Ford and MS-RT, the Ford Pro commercial vehicles conversion partner and design-led automotive engineering company that creates specialised Ford vehicles that stand out on the road, also have announced that MS-RT is to establish a new £4 million vehicle conversion facility at Ford Dagenham.

The new Dagenham facility is intended to provide work for more than 50 new employees when it comes online in 2022, rising to over 120 new jobs when fully operational, helping in the regeneration of one of the UK’s most deprived areas, and is needed due to increasing customer demand for the company’s vehicle conversions both in the U.K. and in a number of European markets.

Thames Freeport – 1,700 acres of development land at the heart of Europe’s largest consumer market – c onnects Ford Dagenham to the ports at London Gateway and Tilbury. The Thames Freeport consortium partners, Ford, DP World London Gateway, and Port of Tilbury are working collaboratively with local authorities, and other public sector bodies such as the Thames Estuary Growth Board (TEGB), Port of London Authority (the PLA) and the South East LEP (SELEP), to catalyse investment opportunities along this strategic corridor, unleashing huge potential for local regeneration, sustainable and inclusive growth.

The Freeport has good onward road, rail and marine connections, alongside well-honed investment promotion, trade facilitation, skills development and automation services. It also is targeting green-tech growth, including future mobility solutions, supported by an Innovation Hub and local authorities committed to economic growth, and cements the Thames Estuary as the UK’s global gateway for trade.

In 2020, Ford was part of the VentilatorChallengeUK consortium which manufactured much needed respiratory ventilators for the National Health Service. Ford transformed an empty warehouse into an ISO 9001-accredited ventilator sub-assembly manufacturing facility in just three weeks – a feat that would usually take a full year. This involved both the Dagenham and wider Ford team, in conjunction with the local community, coming together in challenging times to build, launch and staff the facility with up to five hundred people a day at peak production.

In addition to its role in building the most complex ventilator sub-assemblies, Ford also played the pivotal role in helping to industrialise the production process of the ventilators to enable them to be built in large scale – just as Henry Ford’s moving assembly line led to mass production in the car industry in 1908 with the Model T.

Don't miss out

Be the first to know about the latest news in the automotive and transportation industries through our weekly news round-up and quarterly magazine., automotive purchasing and supply chain | three6zero ltd© 2004-2024.

Site Search

Search our website to find what you’re looking for.

Select Your Language

You can select the language displayed on our website. Click the drop-down menu below and make your selection.

Tickets & Hours

Open monday - saturday.

9:30 a.m. - 5 p.m Last tour leaves at 3 p.m.

Tours begin with a 15 – 20 minute bus ride from The Henry Ford to the Ford Rouge Factory Tour Visitor Center. Due to road construction, buses may experience intermittent delays. See Non-Production Dates below.)

Best Value: Membership

Get the first, the best, and the most rewarding access to unforgettable experiences while helping to preserve the past and fuel the future.

Online Ticket Prices

Museums for All discount: In partnership with Museums for All , The Henry Ford offers discounted $3 general admission, per person/per venue, to Henry Ford Museum of American Innovation, Greenfield Village and Ford Rouge Factory Tour to SNAP/EBT and WIC cardholders and four guests per card. All parking fees are waived.

Please present your SNAP/EBT or WIC card at any ticketing counter to receive this offer.

View the full list of current admission and membership discounts available.

Free admission for members, tour closed.

- All Sundays

- November 23

- December 25

Active Assembly Information

Ford Rouge Factory Tour is an experience housed within Ford Motor Company's Dearborn Truck Plant in partnership with The Henry Ford and the United Auto Workers union.

The Dearborn Truck Plant is a real working factory. As a result, there are many factors that can cause inconsistent active assembly hours. This includes vehicle demand, supply shortages, factory floor renovations and construction, and staffing considerations. The Dearborn Truck Plant does not build vehicles during daily breaks, shift changes, holidays and weekends.

Please note that The Henry Ford cannot control Ford Motor Company’s production schedule and cannot guarantee that guests will see the assembly line in full operation during their visit. The Henry Ford is also not able to refund tickets in the event that vehicles are not being actively assembled.

Regardless of whether vehicles are being actively assembled, guests will be able to view the Dearborn Truck Plant’s final assembly area via a fully accessible suspended walkway at all times. The final assembly area is only one part of Ford Rouge Factory Tour’s 5-part experience. All other parts of the tour remain unaffected.

The Dearborn Truck Plant will not be in active assembly during these dates in 2023, following the plant’s holiday and maintenance schedule. The dates include but aren’t limited to:

- September 2 – 4

- November 11

- November 23 – 26

- December 24, 2023 - January 7, 2024

In addition, active assembly is not available on Saturdays, effective August 1, 2023.

- Digital Editions

- Subcontractor Sourcing Guide

- Latest Newsletter

- Editorial Programme

- Search Engine

- All Things Additive

- Digital Advertising

- Rates & Specs

- 2024 Media Pack

Ford celebrates 90 years at Dagenham

Just over 90 years ago, at 1:16pm on October 1, 1931, the first Ford vehicle rolled off the production line at what was then Ford’s newest global production facility, Ford Dagenham.

Nine decades later – with nearly 11 million cars, trucks and tractors built during 71 years of vehicle production which, if placed end to end, would stretch more than 400,000km or 10 times around the world, and close to 50 million engines produced to date – Dagenham continues to play a major role in Ford’s European operations, building the advanced technology diesel engines that power many of the vehicle maker’s passenger and commercial models.

“Today is about celebrating with our employees the enormous contribution they and their predecessors have made over many generations to the success of Ford Dagenham,” said Kieran Cahill, chairman, Ford Motor Company Limited and vice president, Manufacturing Ford of Europe, speaking at a Ford employee event at the plant.

“Still London’s largest manufacturing site, the fact that Ford Dagenham continues to be such an important part of our European manufacturing operations is testament to our employees’ involvement in the site’s past, present and future.”

Ford Dagenham was confirmed in March of this year as the source of the latest advanced technology diesel engines for the next generation Ford Transit Custom range which will be built by Ford Otosan – Ford’s Turkish joint venture – in Kocaeli, Turkey, from early 2023. The next generation Volkswagen 1-tonne commercial vehicle also will be built in Kocaeli as part of the Ford-Volkswagen Alliance.

“The anticipated incremental engine volumes this creates is expected to help safeguard jobs at Ford Dagenham. By 2025, we anticipate that up to 60% of our entire diesel engine volume will be destined just for the 1-tonne commercial vehicles being built by Ford Otosan,” said Martin Everitt, plant manager, at Dagenham.

Ford also announced earlier this year that the factory will supply the diesel engine for a new light commercial vehicle to be manufactured at its Craiova facility in Romania from 2023.

In addition to diesel engine manufacturing, Ford Dagenham is also home to the company’s transport operations which is responsible for the transport logistics of components and vehicles across the U.K., and to a number of other functions, including information technology.

“What immediately comes to mind when I think of the 90 years anniversary, are the generations of families that have contributed to making this such a fantastic facility and helping us arrive at this milestone. All these people’s contributions over the years have been our true strength in Dagenham,” said Jason Brandon, convenor, Dagenham engine plant.

“They have proven over and over again, both their versatility and their ability to rise to any challenge and when necessary diversify into other areas of manufacturing. We can do anything in Dagenham and I’m sure, notwithstanding the ongoing challenges for the internal combustion engine in the near future, we can secure future Ford opportunities in manufacturing and alternative sectors and give more generations of Ford families the opportunity to work for this great Company.”

“It is awesome to look back at how Dagenham has diversified over the years, making varied world leading products. All employees, past and present, should feel proud of what they have achieved. Looking to the future we have all the right ingredients for success, the most important ingredient being our employees who are motivated and dedicated to taking Dagenham forward into the world of electrified vehicles,” said Debbie Dempsey, transport operations salaried representative, Dagenham.

From 1931 to 2002, Ford Dagenham built some of Ford’s most iconic European vehicles, from the Model Y to the Anglia, and the Zephyr to the Fiesta. Engine manufacturing also has been integral to Ford Dagenham since its earliest days, and while diesel engine production will remain the mainstay of Ford manufacturing operations at Dagenham in the years ahead, Ford also is looking at other opportunities across the Ford Dagenham site.

Announced in late June, the Ford Venari Alliance brings together Ford, the UK market leader in commercial vehicles and Venari, the UK’s largest emergency service vehicle provider, for plans to manufacture an all-new, lightweight front-line ambulance.

www.ford.co.uk

Ford of Britain

Norton expands factory with help from Iscar

Environmentally friendly

Lighter auto parts demand propels Alucast sales

MACH 2024: Top machining technology from NCMT

MACH 2024: The magnificent seven from Prosaw

MACH 2024: Mills goes out of this world

Df precision machinery ltd.

Axe & Status

Hoffmann Group

Mikron Tool

Login / Sign up

Please enter either: Firstname and Lastname or Job Title

Information

- Cookie Policy

- News (7513)

- Features (3207)

- Products (1806)

- Videos (898)

- Literature (185)

- Industry News

- Automotive Industry

Our Other Magazines

Contact Information

- Production Engineering Solutions

- MIT Publishing

- Featherstone House

- 375 High Street

- +44 (0) 1634 830566

- [email protected]

Website by Perception SaS

- Stock Car Racing

- Formula 1 Racing

- Mustang Challenge

- Road Racing

- Drag Racing

- Off-Road Racing

- What's Happening

- Fan Spotlight

- Collector Vehicles

- Clubs & Groups

- Link To Friends

- Driving Schools

- Ford Performance Parts

- Ford Parts Catalog

- Crate Engines

- Performance Packs

- Merchandise

- Performance Vehicles

- Mustang GTD

- Mustang GT3

- Mustang GT4

- Dark Horse R

- Shelby GT500

- Bronco Raptor

- F-150 Raptor

- F-150 Raptor R

- Explorer ST

Enthusiasts

- Enthusiasts /

- Quick Look /

Latest News

Apr 10, 2024 | john m. clor, club connect helps ford host dearborn tour for visiting sao paulo mustang club of brazil.