- Switchable Circuit Breakers

- Push-to-Reset Circuit Breakers

- Waterproof Circuit Breakers

- Auto Reset Circuit Breakers

- Disconnect Circuit Breakers

- Circuit Breaker Accessories

- Part Cross Reference

- Check Stock

- Engineering

Search Mechanical Products Website

Mechanical Products Blog

- Product News

- Press Releases

- Mechanical Products News

What is Trip-Free and Why do I need it?

A Trip-Free circuit breaker / supplementary protector is one that will trip open even if the ON-OFF mechanism is held in the ON position. This is an important characteristic of a circuit breaker as it protects humans and equipment from the hazards of overcurrent. If a breaker is tripping, it is doing its job. When its not doing its job wires can overheat and start fires, motors can burn out, people can be seriously injured. Read further for a more in-depth explanation.

Trip-Free & Trip-Free, Cycling

According to UL1077:

A “Trip-Free” supplementary protector is, “a protector designed so that the contacts cannot be held in the closed position by the operating means during trip command conditions.” In other words, a “Trip-Free” device has the ability to automatically open a circuit in a fault situation, even though its actuator is physically held in the “on” position. This could also be thought of as “Trip-Free, Non-Cycling” (in contrast to the “Trip-Free-Cycling” described below) by UL1077’s requirements, as the contacts should remain in the open position until the actuator is released and reset.

A “Trip-Free, Cycling” supplementary protector (aka, Cycling Trip-Free) is, “a protector designed so that the contacts cannot be held in the closed position by the operating means during trip command conditions, but will reclose when the closing command is maintained. The protector will continue to close momentarily and repeatedly as long as the close command is maintained by the operating means during trip-command conditions.” In other words, a “Trip-Free, Cycling” device, with its actuator held in the “on” position, will act as an automatic-reset protective device as long as the fault condition is present, cycling repeatedly between opened and closed circuit conditions until such time as the fault is removed or the device fails.

While the mechanisms required of “Trip-Free” devices make them generally more expensive than “Trip-Free, Cycling” types, due to various design issues associated with the end product, one type of mechanism may be preferable over the other. Despite the designer’s preference, close attention should be paid to the agency standards applicable to the end product. Dictates within specific standards may mandate the use of one type of operating mechanism over the other.

Get Fresh Blog Updates

Featured resources.

MP Short Thermal Breakers Data Sheet

Product Catalog

Get Updates by Email

Receive updates on Mechanical Products and industry news and trends.

Mechanical Products Resources

Download the Circuit Breaker Selection Guide. Covering ratings of 0.5 – 300 amps, the selection guide is a summary overview of the Series of circuit breakers made by MP. For further details, the individual Series Data Sheets may be downloaded.

Latest MP Articles

- MP Headquarters

- 1112 N. Garfield St

- Lombard, IL 60148

- 630.953.4100

Circuit Protection Devices

Trip-free/nontrip-free circuit breakers.

Circuit breakers are classified as being trip free or nontrip free. A trip-free circuit breaker is a circuit breaker that will trip (open) even if the operating mechanism (ON-OFF switch) is held in the ON position. A nontrip-free circuit breaker can be reset and/or held ON even if an overload or excessive heat condition is present. In other words, a nontrip-free circuit breaker can be bypassed by holding the operating mechanism ON

Trip-free circuit breakers are used on circuits that cannot tolerate overloads and on nonemergency circuits. Examples of these are precision or current sensitive circuits, nonemergency lighting circuits, and nonessential equipment circuits. Nontrip-free circuit breakers are used for circuits that are essential for operations. Examples of these circuits are emergency lighting, required control circuits, and essential equipment circuits.

PAY AFTER YOU PASS! All Courses FREE to Take - Pay only for the Certificate Record Dismiss

Username or Email Address

Remember Me

Trip free operating mechanism definition acc to IEEE C37.04

Medium voltage circuit breakers tripfree definition in the standard are:

If a closing operation is in progress, and a tripping signal (either mechanical or electrical) is received, the circuit breaker shall react as follows:

- If the closing signal and the tripping signal are initiated simultaneously, the circuitbreaker contacts are permitted to close or touch momentarily before opening.

- If the trip circuit uses circuit breaker auxiliary switch contacts or other equivalent contacts, the trip coil of the circuitbreaker cannot be energized until these contacts in the trip circuit are made.

- If the tripping command is initiated mechanically (manually) and held in the actuated position before a closing signal is applied, the circuit breaker main contacts are not permitted to close, even momentarily.

- If the closing signal is initiated before the tripping signal is initiated, the circuit breaker contacts are permitted to close or touch momentarily before opening.

Figure show Eaton trip free MV circuit breaker operation table

Fault clearing currents curve in HVDC hybrid circuit breaker Simulink

Synthetic current test for hvdc circuit breakers, leave a reply cancel reply.

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Don't have an account?

- Mechanical & Electrical

Basics of low-voltage circuit breakers

A circuit breaker is designed to keep an undesirably large amount of current, voltage, or power out of a given part of an electrical circuit. industrial circuit breaker categories tend to follow voltage classes, which are divided according to magnitude. the ieee divides voltage systems into four classes listed in the table titled "ieee voltage classifications..

A circuit breaker is designed to keep an undesirably large amount of current, voltage, or power out of a given part of an electrical circuit.

Industrial circuit breaker categories tend to follow voltage classes, which are divided according to magnitude. The IEEE divides voltage systems into four classes listed in the table titled “IEEE voltage classifications.”

Circuit breakers found in industrial plants accommodate all voltage levels. However, low and medium-voltage circuit breakers comprise the lion’s share of switchgear used in industrial manufacturing plants. The focus of this article is limited to low-voltage circuit breakers.

The main classifications of low-voltage circuit breakers are “toggle” mechanism and two-step stored energy mechanism circuit breakers. The molded-case circuit breaker (MCCB) (Fig. 1) has a toggle mechanism with a distinct tripped position, which is typically midway between on and off.

The low-voltage power circuit breaker (LVPCB) (Fig. 2) has a two-step stored energy mechanism. This type of mechanism uses an energy storage device, such as a spring, that is “charged” and then released, or “discharged,” to close the circuit breaker. The LVPCB is older technology. Therefore the trend is away from LVPCB and toward insulated case circuit breakers (ICCB) because of reduced maintenance. No dust or contaminants can get into the sealed compartments of the ICCB and components are designed to ensure longer life.

Circuit breaker construction

As shown in Fig. 3, most circuit breakers have five main components:

Frame or molded case

Operating mechanism

Arc extinguishers and contacts

Terminal connectors

Trip bar or element.

The frame provides an insulated housing and is used to mount the circuit breaker components. The frame determines the physical size of the circuit breaker and the maximum allowable voltage and current. The operating mechanism provides a means of opening and closing the breaker contacts. In addition to indicating whether the breaker is open or closed, the operating mechanism handle indicates when the breaker has opened automatically (tripped) by moving to a position between on and off. To reset the circuit breaker, first move the handle to the “off” position, and then to the “on” position.

The arc extinguisher confines, divides, and extinguishes the arc drawn between contacts each time the circuit breaker interrupts current. The arc extinguisher is actually a series of contacts that open gradually, dividing the arc and making it easier to confine and extinguish (Fig. 4). Arc extinguishers are generally used in circuit breakers that control a large amount of power, such as those found in power distribution panels. Small power circuit breakers, such as those found in lighting panels, may not have arc extinguishers.

Terminal connectors are electrically connected to the contacts of the circuit breaker and provide the means of connecting the circuit breaker to the circuit. The trip element is the part of the circuit breaker that senses the overload condition and causes the circuit breaker to trip or break the circuit. Some circuit breakers use solid-state trip units, which use current transformers and solid-state circuitry.

Trip elements

The thermal trip element circuit breaker, like a delay fuse, protects a circuit from a small overload that continues for a long time (Fig. 5). The larger the overload, the faster the circuit breaker trips. The thermal element also protects the circuit from temperature increases. A magnetic circuit breaker trips instantly when the preset current is present. In some applications, both types of protection are desired. Rather than use two separate circuit breakers, a single trip element combining thermal and magnetic trip elements is used.

A magnetic trip element circuit breaker uses an electromagnet in series with the circuit load. With normal current, the electromagnet does not have enough attraction to the trip bar to move it; the contacts remain closed. The strength of the magnetic field of the electromagnet increases as current through the coil increases. As soon as the current in the circuit becomes large enough, the trip bar is pulled toward the magnetic element (electromagnet), the contacts are opened, and the current stops.

The amount of current needed to trip the circuit breaker depends on the size of the gap between the trip bar and the magnetic element. On some circuit breakers, this gap, and therefore the trip current, is adjustable.

In the thermal-magnetic trip element circuit breaker, a magnetic element is connected in series with the circuit load, and the load current heats a bimetallic element. Thermal-magnetic trip element operation is detailed in Fig. 6a and 6b.

Trip-free and nontrip-free circuit breakers

Circuit breakers are classified as being trip free or nontrip free. A trip-free circuit breaker is a circuit breaker that trips even if the operating mechanism is held in the “on” position. A nontrip-free circuit breaker can be reset and/or held “on” even if an overload or excessive heat condition is present. In other words, a nontrip-free circuit breaker can be bypassed by holding the operating mechanism “on.”

Trip-free circuit breakers are used on circuits that cannot tolerate overloads and on nonemergency circuits. Examples of these are precision or current sensitive circuits, nonemergency lighting circuits, and nonessential equipment circuits. Nontrip-free circuit breakers are used for circuits that are essential for operations. Examples of these circuits are emergency lighting, required control circuits, and essential equipment circuits.

Circuit breaker maintenance

Circuit breakers that can be accessed for maintenance require careful inspection and periodic cleaning. Before you attempt to work on circuit breakers, check the applicable technical manual carefully. Remove power to the circuit breaker before you work on it. Tag the switch that removes the power from the circuit breaker to ensure that power is not applied while you are working.

Manually operate the circuit breaker several times to ensure the operating mechanism works smoothly. Inspect the contacts for pitting caused by arcing or corrosion. If pitting is present, smooth the contacts with a fine file or number 00 sandpaper.

Be certain the contacts make proper contact when the operating mechanism is in the “on” position.

Check the connections at the terminals to ensure the terminals and wiring are tight and free from corrosion. Check all mounting hardware for tightness and wear. Check all components for wear. Clean the circuit breaker completely.

When you have finished working on the circuit breaker, restore power and remove the tag from the switch that applies power to the circuit.

PLANT ENGINEERING magazine extends its appreciation to Eaton | Cutler-Hammer, E-T-A Circuit Breakers, Rockwell Automation, Schneider Electric, and Siemens Energy & Automation, Inc., for the use of their materials in the preparation of this article.

IEEE voltage classifications

Low-voltage systems.

&1000 Vac

Medium-voltage systems

>1000 Vac to

100,000 Vac*

High-voltage systems

>100,000 Vac to

230,000 Vac

Extra-high voltage systems

>230,000 Vac to 800,000 Vac

*Most medium-voltage systems are rated at 38000 Vac or less.

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.

Related Resources

Privacy Overview

- Motors and Drives

- Energy Efficiency

Circuit breakers with a trip-free design

Phoenix contact's ul 489 listed circuit breakers has a trip-free design that increases safety against closing during an overcurrent event, while the snap-action mechanism eliminates contact welding and reduces contact wear..

Phoenix Contact’s the TMC 8 series UL 489 Listed circuit breakers has a trip-free design that increases safety against closing during an overcurrent event, while the snap-action mechanism eliminates contact welding and reduces contact wear. These circuit breakers safely open circuits during overload and short-circuit events, which prevents the wiring from causing fires. The TMC 8 series breakers are available in 1-, 2-, and 3-pole options, with B-, C-, and D-trip curves, to accommodate a variety of applications. The breakers also include visual trip status indication and several accessories, including auxiliary contact, alarm contact, shunt trip, and cuttable busbars.

Phoenix Contact

www.phoenixcontact.com

– Edited by CFE Media. See more Control Engineering energy and power products .

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.

- Electronic circuit breakers for control systems

- Generator paralleling switchgear

- Circuit breaker for underground mining and metals operations

Minneapolis, US

Memphis, US

Warrendale, US

Privacy Overview

Manual Trip - ON/OFF Switches

Many models are available with a manual trip feature, either standard or as an option.

Others are specifically designed as combined switch/circuit breakers

with rocker, push button, or toggle actuation, styled for front panel mounting. Rocker types are available with illumination as an option.

According to IEC 934/EN 60934:

- R = manual reset only

- M = with manual release but not intended for frequent use as a switch

- S = combined switch/CBE function

- J = automatic reset

Trip Free Mechanism

E-T-A circuit breakers cannot be held closed against an overload. This is achieved through the use of positively trip free designs in accordance with IEC 934/EN 60934 (with the exception of models 1410, 1610, 1658 and 808 which are designed for specialised applications).

Snap-Action Mechanism

The snap-action mechanism featured in many E-T-A models ensures that the contact closing speed is independent of the speed of operation of the actuator (push button, rocker, toggle etc.). The moving contact is retained until the actuator causes a defined force to act in the closing direction of the contacts. Once this force is exceeded, the mechanical retention is overcome allowing the contacts to snap closed (tease free mechanism.) The closing speed is a function of this force alone.

Snap-action mechanisms eliminate contact welding upon switching on to sustained short-circuits and minimise the risk of contact wear over the circuit breakers' life.

- International

Privacy Statement Press Release Contact

TRIP-FREE/NONTRIP-FREE CIRCUIT BREAKERS

Circuit breakers are classified as being trip free or nontrip free.

A trip-free circuit breaker is a circuit breaker that will trip (open) even if the operating mechanism (ON-OFF switch) is held in the ON position. A nontrip-free circuit breaker can be reset and/or held ON even if an overload or excessive heat condition is present. In other words, a nontrip-free circuit breaker can be bypassed by holding the operating mechanism ON.

Trip-free circuit breakers are used on circuits that cannot tolerate overloads and on nonemergency circuits. Examples of these are precision or current sensitive circuits, nonemergency lighting circuits, and nonessential equipment circuits.

Nontrip-free circuit breakers are used for circuits that are essential for operations. Examples of these circuits are emergency lighting, required control circuits, and essential equipment circuits.

TIME DELAY RATINGS

Circuit breakers, like fuses, are rated by the amount of time delay. In circuit breakers the ratings are instantaneous, short time delay, and longtime delay. The delay times of circuit breakers can be used to provide for SELECTIVE TRIPPING.

Selective tripping is used to cause the circuit breaker closest to the faulty circuit to trip. This will remove power from the faulty circuit without affecting other, nonfaulty circuits. Figure 2-22 should help you understand selective tripping.

Figure 2-22. - Use of circuit breakers in a power distribution system.

Figure 2-22 shows a power distribution system using circuit breakers for protection. Circuit breaker 1 (CB1) has the entire current for all seven loads through it. CB2 feeds loads 1, 2, 3, and 4 (through CB4, CB5, CB6, and CB7), and CB3 feeds loads 5, 6, and 7 (through CB8, CB9, and CB10). If all the circuit breakers were rated with the same time delay, an overload on load 5 could cause CB1, CB3, and CB8 to trip. This would remove power from all seven loads, even though load 5 was the only circuit with an overload.

Selective tripping would have CB1 rated as long time delay, CB2 and CB3 rated as short time delay, and CB4 through CB10 rated as instantaneous.

With this arrangement, if load 5 had an overload, only CB8 would trip. CB8 would remove the power from load 5 before CB1 or CB3 could react to the overload.

In this way, only load 5 would be affected and the other circuits would continue to operate.

PHYSICAL TYPES OF CIRCUIT BREAKER S

All the circuit breakers presented so far in this chapter have been physically large, designed to control large amounts of power, and used a type of toggle operating mechanism. Not all circuit breakers are of this type. The circuit breaker in figure 2-23 is physically large and controls large amounts of power; but the operating mechanism is not a toggle. Except for the difference in the operating mechanism, this circuit breaker is identical to the circuit breakers already presented.

Figure 2-23. - Circuit breaker with an operating handle.

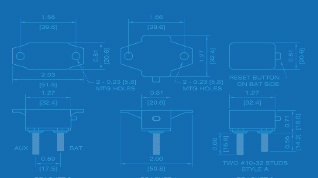

Circuit breakers used for low power protection, such as 28-volt dc, 30 amperes, can be physically small. With low power use, arc extinguishers are not required, and so are not used in the construction of these circuit breakers . Figure 2-24 shows a low power circuit breaker of the push-button or push-pull type. This circuit breaker has a thermal trip element (the bimetallic disk) and is nontrip-free. The push button is the operating mechanism of this circuit breaker .

Figure 2-24. - Push-button circuit breaker.

You will find other physical types of circuit breakers as you work with electrical circuits. They are found in power distribution systems, lighting panels, and even on individual pieces of equipment. Regardless of the physical size and the amount of power through the circuit breaker, the basic operating principles of circuit breakers apply.

- Transformers

What are Trip Free and non-Trip Free Circuit Breakers

Filipino Engineer

What is a trip free circuit breaker?

A trip-free circuit breaker is a type of circuit breaker that cannot be forcibly held closed (or in the "on" position) during an overcurrent or fault condition. In simpler terms, even if someone tries to manually keep the circuit breaker "on", it will still "trip" or automatically turn off if a fault is detected. A trip-free circuit breaker is commonly used in electrical distribution systems to prevent damage to electrical equipment and circuits in the event of overcurrent or short-circuit conditions. The term "trip-free" refers to a specific feature of the circuit breaker, which distinguishes it from other types of circuit breakers.

In a conventional circuit breaker, there are typically two modes of operation:

A trip-free circuit breaker, on the other hand, has a feature that prevents the immediate resetting of the circuit breaker while there is still an ongoing fault condition or overcurrent situation. In other words, even if someone tries to manually reset the circuit breaker, it will not reset until the fault is cleared or the overcurrent condition subsides.

This feature is designed to enhance safety by ensuring that the circuit breaker remains in the "OFF" position as long as there is a potentially hazardous electrical fault. It prevents accidental or deliberate attempts to reset the circuit breaker in situations where doing so could lead to electrical hazards or equipment damage.

Importance of Trip-Free Circuit Breakers

Circuit Breakers, Trip-Free, Aircraft General Specification For AS58091

Sae mobilus.

Subscribers can view annotate, and download all of SAE's content. Learn More »

Access SAE MOBILUS »

Thermal Effectiveness of Sleeve/Tubing/Tape Insulation

J2302_202206

View Details

Test Method for Measuring the Relative Drapeability of Flexible Insulation Materials

J1325_201110

Heavy-Duty Starter Remanufacturing Procedures

J2237_200811

Get Involved

Want to participate in updating this standard?

Need HELP ?

Tehnical support, send us an email, get your local contact, close-open operation (short-circuit) time results interpretation, introduction.

Close-Open operation (C-O, trip-free) simulates closing on a short circuit. In the actual event, the breaker closes first, then the protection relay system detects the short circuit and trips the breaker.

In the test event, the timing device can be programmed to start a trip command as soon as the contacts close. This gives the fastest short-circuit time (C-O time) operation the breaker is capable of doing.

Most high voltage circuit breaker mechanisms are characterized as being trip-free. Performing trip-free operation simply requires the circuit breaker to be able to open without any delay once the auxiliary switch (contact), which controls the application of the electric signal to the operating coils, closes. Under these conditions, the main contacts of the circuit breaker are allowed to touch instantly. This means the trip-free characteristic requires the circuit breaker to open at any instant that a trip command is issued to the unit, even if the circuit breaker is in the process of closing. To achieve this, the mechanism, interrupters, and drive system must be able to withstand the forces of the sudden change of direction.

In other cases, a circuit breaker must close before it opens.

For example, let’s suppose a breaker is being closed manually by operating the contact closing mechanism or remotely. While the contacts are in the process of closing suppose a fault occurs in the system with the relay closing the trip circuit of the breaker. The trip-free mechanism allows the circuit breaker to be tripped by the relay even if the contacts are in the process of closing.

Close-Open Operation

The major international standards for circuit breakers are IEC® and ANSI® /IEEE®. One section of IEC 62271-100 “High-voltage alternating current circuit-breakers” standard describes the circuit-breaker-related time definitions.

C-O (close-open) time definition according to IEC is:

“Interval of time between the instant when the contacts touch in the first pole during a closing operation and the instant when the arcing contacts have separated in all poles during the subsequent opening operation.”

This standard also states:

“Unless otherwise stated, it is assumed the opening release incorporated in the circuit breaker is energized at the instant when the contacts touch in the first pole during closing. This represents the minimum close-open time.”

Close-open (measured during the test) should be distinguished from the make-break time (measured when a circuit breaker is under load), as illustrated in Figure 1. According to the IEC standard make-break time is:

“Interval of time between the initiation of current flow in the first pole during a closing operation and the end of the arcing time during the subsequent opening operation (Figure 1).

NOTE: The make-break time may vary due to the variation of the pre-arcing time.”

C-O time (also called dwell time) is the amount of time the breaker is in the closed position during a close-open operation. C-O time value is compared to the manufacturer’s specifications. For the puffer SF6 circuit breakers, too short C-O time (during trip-free operation) compared to specification can cause longer arcing time or in the worst case a failure to break a short-circuit during the subsequent opening. It is because too short C-O time could mean the circuit breaker didn’t get time to close enough (during closing in the trip-free operation) to provide compression volume large enough to produce the blast of SF6 gas to extinguish the arc.

Longer C-O time means longer short-circuit time during the potential fault. Due to the high electric current, there may be high thermal stress in the insulation and conducting parts of the circuit breaker. As the thermal stress in the circuit breaker is proportional to the period of the short circuit, the breaking capacity of the circuit breaker depends upon the operating time which is C-O time.

When checking the C-O time of the breaker during timing tests , the auxiliary switch (contact) adjustment should be checked. The auxiliary switches are adjustable for most high voltage circuit breaker operating mechanisms. These switches are adjusted at the factory to set close-open time and close open travel during a trip-free or C-O operation of the breaker according to the manufacturer’s specifications. In case the C-O time value is out of range, the auxiliary switches can be adjusted to bring the C-O time within tolerance.

C-O Timing Results in the DV-Win Software

The contact’s close-open times for a circuit breaker with one break per phase are displayed in Figure 2. In the graphic display, C-O times are marked for each pole and for the breaker separately. Also, as shown in Figure 2. C-O time is calculated and displayed in the tab Numerical results for each phase and breaker separately.

For a circuit breaker with two breaks per phase, graphical results for C-O operation are displayed in Figure 3. In the graphic display, C-O times are marked for each contact separately. Also, C-O time is calculated and displayed in the tab Numerical results for each contact, phase, and breaker separately.

NOTE: For a circuit breaker with more than one break per phase, phase C-O time is calculated as the interval of time between the instant when the last contact touched in the pole during closing and the instant when the first contact separated in the pole during subsequent O operation. Breaker C-O time is an interval of time between the instant when the metallic continuity is established in the first pole during a closing operation and the instant when all poles have separated during the subsequent opening operation.

As can be seen from Figure 3, the C-O time in phase A (14.6 ms) is much shorter than the C-O time of the other two phases (34 ms and 29.2 ms). Also, it is much shorter than the minimum opening time (25 ms) for this circuit breaker. Since the closing time of phase A is within tolerance (i.e. phase A is not slower at closing which could cause shorter C-O time) it indicates there is no problem with the operating mechanism of phase A but with auxiliary contact of type “a” adjustment. It tells the auxiliary contact “a” is closing earlier than it should, causing phase A to open faster at the next subsequent opening.

To download the .pdf format of this article, please log in and visit the following link .

September 19, 2019

More Readings

Ct testing using dv power’s new model cva500, middle east energy 2024, battery college – closing bell for registration , using dvtest (drm) method to detect bad contacts inside on-load tap changers .

- svg]:stroke-primary"> 826K

- svg]:stroke-primary"> 622K

- svg]:stroke-primary"> 246K

- svg]:stroke-primary"> 45K

Why Is My Circuit Breaker Tripping? 4 Potential Problems and Solutions

By: Glenda Taylor , Bob Vila , Evelyn Auer

Updated on Dec 21, 2023 8:55 PM EST

6 minute read

Photo: istockphoto.com

We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

Q: Every few hours—sometimes minutes!—my living room and one side of my kitchen lose electrical power. I’ll check the breaker panel and, sure enough, a circuit breaker has tripped…again. Should I call an electrician, or is there a simple DIY fix I can try first?

A: While it’s frustrating when a circuit breaker keeps tripping, they are important safety mechanisms. Designed to shut off the electrical current when something goes wrong, circuit breakers are one of the best ways of protecting a home from an electrical fire. “When a circuit breaker trips, typically it is because we use too much electricity, which causes it to overload and turn off,” says Christopher Haas, expert electrician and owner of Haas & Sons Electric in Millersville, Maryland. For those who need an electrical panels 101 refresher course or aren’t sure how to reset circuit breakers, each breaker has an on/off switch and controls a separate electrical circuit in the home. When a breaker trips, its switch automatically flips “off,” and it must be manually turned back on to restore electricity to the circuit. For those wondering, “Is it dangerous if a circuit breaker keeps tripping?” the answer is that it can be, depending on the source of the problem. An electrician can ultimately deal with the root issue, but a little sleuthing will reveal whether it’s something that’s easily remedied.

In many cases, the cause of a circuit breaking tripping is an overloaded circuit.

A circuit overloads when more electrical current is being drawn through the wires than they can handle, tripping the circuit breaker. If this happens, there may be a few additional signs:

- Buzzing noises coming from outlets

- Devices charging slowly

- Electrical outlets not working

- Flickering lights

- Scorch marks on outlets and light switches

If a circuit breaker keeps tripping in one room, homeowners can test for circuit overload by turning off all the switches in the affected area and unplugging all appliances and devices. After the breaker is flipped back on, the devices can be turned back on one at a time, with homeowners waiting a few minutes in between to see if the circuit remains on. If the breaker trips before all the appliances are turned on, the experiment can be repeated, this time turning them on in a different order. It may be necessary to do this several times to find out how many appliances can be operated at once before the circuit overloads.

“As a short-term solution, you can unplug unnecessary appliances to prevent tripping circuit breakers. You may still get some trips, but you can limit them by unplugging devices that you don’t need to use,” advises Dan Mock, vice president of operations at Mister Sparky , an electrical company with 90 locations in the U.S. The best long-term solution, however, is to pay an electrician for the cost to rewire the house and add additional circuits. The cost to replace an electrical panel is about $1,274 on average.

Other times, the issue may be caused by a short circuit.

A “short” circuit means that two wires that should not be coming into contact are inadvertently touching, triggering a sudden surge of electricity through the wires. A short can occur in an outlet, a switch, or within an appliance if wires are loose or have been chewed through by mice or pets. Some signs of a short circuit include:

- Popping sounds

- Discolored outlets or switches

- Burning smells

Testing to see if an appliance has a short is similar to testing for an overloaded circuit. When an appliance that has a short in its wiring is turned on, it will immediately trip the circuit. Homeowners can also try plugging it into an outlet in a different room. If the breaker for that room trips, there’s a short in the appliance (if it’s unclear what breaker goes to what room, the breaker can be identified with one of the best circuit breaker finders ). Electrical shorts can be a major fire hazard, so it’s a good idea to call a licensed electrician for this circuit breaker repair. It’s wise to stop using the outlet or appliance until a pro takes care of the problem.

Another potential cause of a circuit breaker tripping is a ground fault.

A ground fault occurs when the electricity running through a home’s wiring diverts from the wiring loop and travels to the ground, usually due to faulty wiring or water infiltration in an outlet or switch box. Water is a conductor, which is why walking through puddles is often listed as something not to do in a power outage in case of downed power lines. Once water makes contact with wires, electricity can jump from the wiring loop and follow the water trail. This creates a surge in electricity leading to a tripped circuit breaker. If a person comes in contact with the electricity that is on its way to the ground, this can result in electrocution. Homeowners may notice a few signs of a ground fault, including:

- Tripped GFCI (ground fault circuit interrupter) outlets;

- A burning smell coming from an outlet; and

- Lights flickering.

Newer electrical breakers have features designed to protect against the danger of ground faults. According to Haas, “Ground fault breakers sense electricity going to earth as opposed to going through the wires of the circuit. You’ll find [these] for bathrooms, kitchens, garages, exteriors, and basements.” GFCI outlets are another safety feature that shut off the electric current within a fraction of a second of sensing a ground fault.

If a ground fault is the problem, the cause of the errant water must be discovered and repaired, and any damaged wiring must also be replaced. It’s also a good idea to install GFCI outlets in rooms where water is commonly used. A GFCI outlet costs $210 on average.

Sometimes a bad or worn-out circuit breaker can be the culprit.

In some cases, the circuit breaker itself may be faulty. Breakers that are old, damaged, or were installed incorrectly may trip frequently for no apparent reason. Alternatively, faulty breakers may not trip when they are supposed to, leaving the home at risk of electrical fire. Some signs of a bad circuit breaker include:

- The circuit breaker getting hot and tripping frequently;

- The circuit breaker won’t reset;

- It has been over 10 years since the breaker was last serviced; and

- The breaker has scorch marks.

An important electrical safety tip to keep in mind is that resetting a breaker over and over again can cause what is called an arc flash, which is a small electrical explosion that can be deadly. If resetting the breaker once does not remedy the issue, it’s a good idea for the homeowner to hire an electrician near them who knows how to replace a circuit breaker safely. Mock warns, “Don’t take any chances with circuit breakers. Instead, call a licensed electrician who knows the safe ways to replace breaker boxes, upgrade circuits, and diagnose potential electrical problems in your home.” Wiring a breaker box is a job to leave to an experienced electrician.

A professional electrician can help determine the specific cause of a frequently tripping circuit breaker.

Most circuit breaker problems—aside from those explained in the sections above—will need to be inspected and addressed by a licensed electrician. According to the Electrical Safety Foundation International (ESFI) , each year “thousands of people in the United States are critically injured and electrocuted as a result of electrical fires, accidents, [or] electrocution in their own homes.” While homeowners may be tempted to save on electrician costs by attempting circuit breaker replacement or repair themselves, electrical work is not suitable for casual DIYers. “Yes, you have to pay, but you can save many hours of head-scratching by hiring an electrician. Electricians will also have all the right tools for diagnosing and repairing the circuit,” Haas adds. “Lastly, they will come with a warranty/guarantee should something arise, and they will typically return at no additional cost.”

The Government Is Paying People to Upgrade Their Home Comfort, Here’s Why

a]:text-primary [&>a]underline [&>a]:hover:hover-link">By: Tony Carrick

The 20 Best Lawn Care Products for a Lush and Healthy Lawn

a]:text-primary [&>a]underline [&>a]:hover:hover-link">By: Deirdre Mundorf

Understanding Trip Circuit: Breakers, Overloads, and Solutions for Short Circuits

Understanding circuit breakers and how to deal with constant tripping.

When the circuit breaker in your home trips, it’s important to reset it in the fusebox to restore power. This may require a trip under the stairs or down to the garage, depending on where your circuit breaker is located. Circuit breakers are designed to interrupt the electrical current when the switch is tripped, ensuring the safety of your electrical system.

While circuit breakers are essential safety devices, constant tripping and repeated resetting can be frustrating. However, if you can identify the cause of the frequent trips, you can take steps to address the issue.

What is a Circuit Breaker?

Every home and business premises have electrical circuits controlled and protected by a switching device located in a consumer unit or fuse panel. Modern systems typically use circuit breakers for control and protection, while older systems might still rely on fuses that blow when overloaded. The main purpose of a circuit breaker is to cut off the flow of electricity to prevent circuits from overheating, which can cause damage and even lead to electrical fires.

How Does a Circuit Breaker Work?

A circuit breaker is a switching device that can be operated manually or automatically. It trips and disconnects the circuit to cut off the electricity supply if there’s an excessive current flow or an overload that the switch can’t handle. The circuit breaker is designed to protect your electrical power system and any devices connected to it.

Why Does a Circuit Breaker Trip?

A circuit breaker will trip when there is an electrical fault that could damage the circuit. This fault typically falls into three categories:

- Overloads: The most common reason for circuit breakers to trip is overloading. This occurs when you draw more electrical power from a circuit than it can handle. For example, running multiple appliances simultaneously or exceeding the circuit’s capacity. When a circuit overheats due to an overload, it puts all connected appliances at risk. The circuit breaker ensures the wires don’t excessively heat up and protects against fire hazards.

- Power Surges: Power surges can also cause circuit breakers to trip. These surges happen when there is a sudden increase in electrical voltage, often caused by lightning strikes or faulty wiring in the electrical system. Circuit breakers act as a defense mechanism against power surges by cutting off the excessive flow of electricity.

- Faulty Components: Another reason for circuit breakers to trip is faulty components within the electrical system. This can include damaged wires, short circuits, or defective appliances. When these faults occur, the circuit breaker detects the problem and interrupts the current flow to prevent damage.

Dealing with Constant Tripping

If your circuit breaker is frequently tripping, it indicates that you are demanding too much power from the circuit. To resolve this issue:

- Redistribute Appliances: Distribute your appliances and devices onto different circuits. Avoid overloading a single circuit by spreading the load across multiple ones. This ensures that each circuit operates within its designed capacity.

- Upgrade Your Electrical System: If your system doesn’t have enough circuits to meet modern demands, consider upgrading your electrical system. This may involve installing additional circuits or replacing outdated wiring and panels. A professional electrician can assess your needs and recommend the best solution.

By understanding how circuit breakers work and taking appropriate measures, you can prevent constant tripping, protect your electrical system, and ensure the safety of your home or business.

Understanding Circuit Breaker Tripping: Short Circuits and Ground Fault Surges

Have you ever experienced a sudden power outage in your home or office? Chances are, it was due to a circuit breaker tripping. Understanding the causes of circuit breaker tripping, such as short circuits and ground fault surges, is crucial for ensuring the safety of your electrical system. Let’s explore these common issues in more detail:

1. Short Circuits

Short circuits are a common reason for circuit breaker tripping and should be taken seriously due to their potential danger. A short circuit occurs when a live wire comes into contact with a neutral wire, resulting in an abnormal electrical connection. This can happen in electrical outlets or due to faulty wiring in appliances or plugs.

When a short circuit occurs, the normal electrical resistance is overridden, causing an excessive flow of current through the circuit. This generates excessive heat, which can lead to fires. If you notice a burning smell or dark discoloration around the circuit breaker, it is an indication of a short circuit.

2. Ground Fault Surges

Similar to short circuits, ground fault surges involve a live wire touching a bare copper ground wire or a part of a metal outlet box connected to the ground wire. When this happens, an excess flow of electricity occurs, triggering the circuit breaker to trip. Discoloration around the outlet is also a visible sign of a ground fault surge.

Both short circuits and ground fault surges are not only inconvenient but also pose serious risks to your safety. If your circuit breakers frequently trip, it is crucial to seek professional assistance to identify and resolve the underlying electrical issues. Attempting to solve electrical problems on your own can lead to further complications and put your premises at risk.

Remember, the safety of your electrical system should be entrusted to trained professionals. Don’t hesitate to call for professional help to ensure the proper functioning and safety of your electrical circuits.

Leave a Comment Cancel Reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

IMAGES

VIDEO

COMMENTS

Definitions. In the most general definition of "Trip-Free," the contacts of the circuit breaker must return to the open position and remain there when an opening operation follows a closing operation, regardless of whether the closing signal, force, or action is maintained. A common variant is called "Electrically Trip-Free.".

A trip-free circuit breaker is a device that will trip open even if the ON-OFF mechanism is held in the ON position. It protects humans and equipment from the hazards of overcurrent. Learn the difference between trip-free and trip-free cycling, the standards and the benefits of trip-free circuit breakers.

A trip-free circuit breaker is a circuit breaker that will trip (open) even if the operating mechanism (ON-OFF switch) is held in the ON position. A nontrip-free circuit breaker can be reset and/or held ON even if an overload or excessive heat condition is present. In other words, a nontrip-free circuit breaker can be bypassed by holding the ...

• "Mechanically trip-free" operations refer to a mechanical release mechanism that can open the medium voltage circuit breaker regardless of whether any closing release device operated by any means is activated or maintained.Medium voltage circuit breakers can also be hydraulically trip-free or pneumatically trip-free if they contain a ...

Thermal-magnetic tripping units // The thermomagnetic trip unit consists of two parts: The thermal trip unit - Made up by a bimetal thermal device which actuates the opening of a circuit breaker with a delay depending on the overcurrent value. This trip unit is intended for the protection against overloads.. The magnetic trip unit - Made up by an electromagnetic device, with fixed (fixed ...

If you suspect a short circuit, unplug your appliances and check the wires for melted coverings. You might also notice a burning smell coming from the outlet. Call in a professional electrician to find the source of the problem. 3. Circuit Overload. Circuit overloads are the most common reason that a breaker trips.

Trip free operating mechanism definition acc to IEEE C37.04. Medium voltage circuit breakers tripfree definition in the standard are: If a closing operation is in progress, and a tripping signal (either mechanical or electrical) is received, the circuit breaker shall react as follows: simultaneously, the circuitbreaker contacts are permitted to ...

A nontrip-free circuit breaker can be reset and/or held "on" even if an overload or excessive heat condition is present. In other words, a nontrip-free circuit breaker can be bypassed by holding the operating mechanism "on." Trip-free circuit breakers are used on circuits that cannot tolerate overloads and on nonemergency circuits.

By Phoenix Contact July 3, 2016. Phoenix Contact's the TMC 8 series UL 489 Listed circuit breakers has a trip-free design that increases safety against closing during an overcurrent event, while the snap-action mechanism eliminates contact welding and reduces contact wear. These circuit breakers safely open circuits during overload and short ...

Trip Free Mechanism E-T-A circuit breakers cannot be held closed against an overload. This is achieved through the use of positively trip free designs in accordance with IEC 934/EN 60934 (with the exception of models 1410, 1610, 1658 and 808 which are designed for specialised applications).

A trip-free circuit breaker is a circuit breaker that will trip (open) even if the operating mechanism (ON-OFF switch) is held in the ON position. A nontrip-free circuit breaker can be reset and/or held ON even if an overload or excessive heat condition is present. In other words, a nontrip-free circuit breaker can be bypassed by holding the ...

The trip free mechanism/ Anti pumping feature permits the circuit breaker to be tripped by protective relay even if it is under process of closing. Thus auxiliary relay (or sometimes the inbuilt feature of circuit breaker) which prevent alternate tripping and closing of the circuit breaker if closing push button is held close during fault is ...

Learn the difference between trip-free and nontrip-free circuit breakers, how they are rated, and how they are used for different types of circuits. Trip-free circuit breakers are openable by holding the operating mechanism, while nontrip-free circuit breakers can be bypassed by holding the operating mechanism.

Trip-free circuit-breaker is a circuit-breaker, the moving contacts of which return to and remain in the open position when the automatic opening operation is initiated after the initiation of the closing operation, even if the closing command is maintained. IEC 60898-1-2019.

Non-Trip Free circuit breakers are used in circuits which are critical for plant operation and for safety. In these systems, it may be economical to lose a motor or a heater than to interrupt the manufacturing process. In these circuit breakers, the trip function can be bypassed by forcing the circuit breaker to the on position. ...

A trip-free circuit breaker is commonly used in electrical distribution systems to prevent damage to electrical equipment and circuits in the event of overcurrent or short-circuit conditions. The term "trip-free" refers to a specific feature of the circuit breaker, which distinguishes it from other types of circuit breakers. ...

The trip unit is the part of the circuit breaker that determines when the contacts will open automatically. In a thermal-magnetic circuit breaker, the trip unit includes elements designed to sense the heat resulting from an overload condition and the high current resulting from a short circuit. In addition, some thermal magnetic circuit ...

AS58091. The primary function of this specification is to cover the general requirements of one-, two-, and three-pole trip-free circuit breakers for use in aircraft electric systems conforming to MIL-STD-704. As a secondary function, this specification may possibly cover the general requirements of one-, two- and three-pole circuit breakers ...

adjustable circuit breaker is set to trip instantaneously. 15 - INSTANTANEOUS TRIP: a qualifying term indicating that no delay is pur-posely introduced in the automatic tripping of the circuit breaker. 16 - INSTANTANEOUS TRIP CIRCUIT BREAKER (MOTOR CIRCUIT PROTEC-TOR OR CIRCUIT INTERRUPTER): is one intended to provide short circuit protection only.

BEST FOR RV USE: T Tocas 60 Amp Surface Mount Circuit Breaker. BEST FOR COMMERCIAL USE: Rkurck 30 Amp Push-Button Circuit Breaker. BEST 50A: Eaton 50A 2-Pole Circuit Breaker. BEST 100A: Siemens ...

Close-Open Operation (Short-Circuit) Time Results Interpretation. Introduction. Close-Open operation (C-O, trip-free) simulates closing on a short circuit. In the actual event, the breaker closes first, then the protection relay system detects the short circuit and trips the breaker. In the test event, the timing device can be programmed to ...

Find out the cost to replace an electrical panel. On every breaker, there will be an "On" and "Off" position. On a tripped breaker, the handle will be in the middle, neither On nor Off. To reset, flip the handle to Off first, then to On. Stand to the side of the panel and turn your face away when flipping breakers.

Devices charging slowly. Electrical outlets not working. Flickering lights. Scorch marks on outlets and light switches. If a circuit breaker keeps tripping in one room, homeowners can test for ...

A circuit breaker will trip when there is an electrical fault that could damage the circuit. This fault typically falls into three categories: Overloads: The most common reason for circuit breakers to trip is overloading. This occurs when you draw more electrical power from a circuit than it can handle. For example, running multiple appliances ...